Ceramic Capillary Bonding Capillary Ukuze semiconductor emaphaketheni

Isicelo somkhiqizo

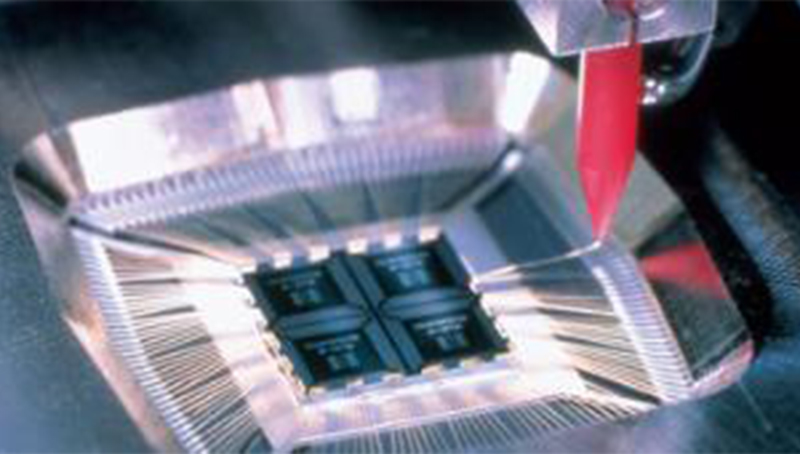

I-Ceramic Capillary iyithuluzi le-ceramic eliyi-axisymmetric elinezimbobo eziqonde mpo, okuyingxenye enembile yesakhiwo se-ceramic se-ceramic.Mayelana nokusetshenziswa, i-Ceramic Capillary isetshenziswa njengethuluzi lokuhlanganisa izintambo ohlelweni lokuhlanganisa izintambo.I-WireBonding ingenza insimbi eholayo ishiselwe eduze ne-substrate pad ngokusebenzisa izintambo zensimbi ezincane (ithusi, igolide, njll.) kanye nokushisa, ukucindezela, namandla e-ultrasonic, ukuze kubonakale ukuxhumana kukagesi phakathi kwama-chips nama-substrates kanye nokushintshana kolwazi phakathi ama-chips.Ifanele ukuhlanganiswa nokupakishwa kwe-SCR, i-SAW, i-LED, i-diode, i-triode, i-IC chip namanye ama-circuits.

Izinzuzo zomkhiqizo

I-OPT Cutting Tools Co., LTD.itholakala eShenzhen, Guangdong, China.Yinkampani ehlanganisa ukukhiqiza, ukuthengisa, ucwaningo kanye nentuthuko.Futhi angenza ukuklama nokwenza imidwebo, izinto zokwakha kanye namathuluzi angajwayelekile.Yamukela ngokuqinile izinto zokukhiqiza zasekhaya zomugqa wokuqala ukuze uqinisekise ukuzinza kwamaqoqo ahlukene wezinto.Lawula ngokuqinile inqubo yokukhiqiza ukuze uqinisekise ikhwalithi yamathuluzi.Le nkampani inamandla amakhulu ezobuchwepheshe, amandla okukhiqiza aqinile, ukuphathwa kwesayensi, ngenhloso "yokusinda ngekhwalithi, intuthuko ngesithunzi", futhi iqhubekela phambili njalo ukuhlinzeka amakhasimende ngemikhiqizo engcono.

Ukulethwa okunembile, isevisi enhle

1. I-OPT Cutting Tools inokukhiqiza kwayo okuphelele, ukukhiqiza kanye nohlelo lokuthutha.Ngesikhathi sokulethwa.

2. Ukuxhumana nokushintshana okukodwa kuya kokukodwa kungenziwa namakhasimende ukuze kuhlinzekwe kangcono amakhasimende ngamathuluzi angcono kakhulu wokuhlanganisa i-Ceramic.

3. Yenza ngokwezifiso amapharamitha akhethekile ngokwezidingo ezikhethekile zekhasimende;

Ukuthuthukiswa kwe-Bonding Capillary Material

Ngokwesisekelo se-aluminium oxide yasekuqaleni, i-zirconia, i-chromium oxide, njll. zengezwa ukwenza ukwakheka kwamangqamuzana e-Ceramic Capillary kuhlangene, ngobulukhuni obuphakeme, ukumelana nokugqoka okungcono nokuphila isikhathi eside kwenkonzo.Yehlisa ukuguga nokushintsha izikhathi zeceramic cleaver tip ngesikhathi sokushisela izintambo.

Ukunemba okuphezulu, ukunemba okuphezulu kwe-dimensional, ukwenza imishini encane kanye nendawo ebushelelezi.

Umkhiqizo unokunemba okuphezulu, ukunemba okuphezulu kwe-dimensional, inani elincane lomshini kanye nendawo ebushelelezi.

Isakhiwo seCeramic Capillary sinembe kakhulu futhi siyinkimbinkimbi, futhi ubukhulu bayo obuyinhloko bunomthelela omkhulu kumphumela wokubopha ucingo.I-OPT Cutting Tools ilawula ngokuqinile inqubo yokukhiqiza ukuze kuqinisekiswe ikhwalithi yamathuluzi.Ukuze uthole ukunemba okuphezulu komkhiqizo, ukunemba okuphezulu kwe-dimensional, ukukhanda okuncane, kanye nendawo ebushelelezi.Inkampani yethu izibophezele ku-R&D kanye nokukhiqiza amathuluzi e-ceramic bonding asezingeni eliphakathi nendawo aphezulu emkhakheni wokupakishwa kwe-IC.I-Ceramic powder kanye nezingxenye zombungu zithuthukiswa ngokuphelele futhi zikhiqizwa ngokuzimela.

![]()

I-BPP:150μm(μm/mil)

| Ingxenye NO. | WD | H | T | CD | OR | α | Θ | CA |

| A-1 | 38/1.5 | 51/2.0 | 229/9.0 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-2 | 38/1.5 | 51/2.0 | 152/6.0 | 66/2.6 | 10/0.4 | 0° | 30° | 90° |

| A-3 | 38/1.5 | 51/2.0 | 229/9.0 | 86/3.4 | 102/4.0 | 0° | 30° | 90° |

| A-4 | 38/1.5 | 51/2.0 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90′ |

| A-5 | 38/1.5 | 56/2.2 | 239/9.4 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-6 | 38/1.5 | 56/2.2 | 229/9.0 | 96/3.8 | 102/4.0 | 0° | 30° | 90° |

| A-7 | 38/1.5 | 56/2.2 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90° |

| A-8 | 38/1.5 | 64/2.5 | 239/9.4 | 102/4.0 | 38/1.5 | 6° | 30° | 120° |

| A-9 | 38/1.5 | 64/2.5 | 203/8.0 | 89/3.5 | 61/2.4 | 0° | 30° | 90° |

| A-10 | 51/2.0 | 64/2.5 | 191/7.5 | 81/3.2 | B/0.3 | 0° | 30° | 90° |

| A-11 | 51/2.0 | 64/2.5 | 292/11.5 | 102/4.0 | 127/5.0 | 0° | 30° | 90° |

| A-12 | 51/2.0 | 76/3.0 | 356/14.0 | 122/4.8 | 152/6.0 | 0° | 30° | 90° |

| A-13 | 51/2.0 | 89/3.5 | 419/16.5 | 135/5.3 | 178/7.0 | 0° | 30° | 90° |

| A-14 | 51.64/2.0.2.5 | 76/3.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-15 | 64.76/2.5.3.0 | 89/3.5 | 330/13.0 | 127/5.0 | 64/2.5 | 8° | 30° | 120° |

| A-16 | 64.76/2.5.3.0 | 102/4.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-17 | 76/3.0 | 102/4.0 | 483/19.0 | 168/6.6 | 203/8.0 | 0° | 30° | 90° |

I-BPP:140μm(μm/mil)

| Ingxenye NO. | WD | H | T | CD | OR | α | Θ | CA |

| B-1 | 22/0.9 | 33/1.3 | 140/5.5 | 64/2.5 | 20/0.8 | 8° | 30° | 120° |

| B-2 | 25/1.0 | 38/1.5 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-3 | 25/1.0 | 38/1.5 | 89/3.5 | 53/2.1 | B/0.3 | 0° | 30° | 90° |

| B-4 | 25/1.0 | 38/1.5 | 114/4.5 | 53/2.1 | 8/0.3 | 0° | 30° | 90° |

| B-5 | 25/1.0 | 38/1.5 | 178/7.0 | 64/2.5 | 76/3.0 | 0° | 30° | 90° |

| B-6 | 25/1.0 | 38/1.5 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-7 | 25/1.0 | 43/1.7 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-8 | 25/1.0 | 43/1.7 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-9 | 25.30/1.0.1.2 | 43/1.7 | 229/9.0 | 74/2.9 | 30/1.2 | 8° | 30° | 120° |

| B-10 | 25.30/1.0.1.2 | 43/1.7 | 152/6.0 | 59/2.3 | B/0.3 | 8° | 30° | 120° |

| B-11 | 25.30/1.0.1.2 | 43/1.7 | 203/8.0 | 74/2.9 | 89/3.5 | 0° | 30° | 90° |

| B-12 | 25.30/1.0.1.2 | 46/1.8 | 229/9.0 | 74/2.9 | 38/1.5 | 8° | 30° | 120° |

| B-13 | 30/1.2 | 46/1.8 | 203/8.0 | 76/3.0 | 89/3.5 | 0° | 30° | 90° |

I-BPP: 100μm(μm/mil)

| Ingxenye NO. | WD | H | T | CD | OR | α | Θ | CA |

| C-1 | 25/1.0 | 38/1.5 | 130/5.1 | 53/2.1 | 30/1.2 | 11 | 30° | 90° |

| C-2 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 11 | 30° | 90° |

| C-3 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 8′ | 30° | 90° |

| C-4 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 4′ | 30° | 90° |

| C-5 | 30/1.2 | 41/1.6 | 130/5.1 | 59/2.3 | 30/1.2 | 11 | 30° | 90° |

I-BPP: 90μm(μm/mil)

| Ingxenye NO. | WD | H | T | CD | OR | α | Θ | CA |

| D-1 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 11° | 30° | 90° |

| D-2 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

| D-3 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| D-4 | 25/1.0 | 35/1.4 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-5 | 30/1.2 | 38/1.5 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-6 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 1310.5 | 8° | 30° | 90° |

| D-7 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 13/0.5 | 4° | 30° | 90° |

I-BPP: 80μm(μm/mil)

| Ingxenye NO. | WD | H | T | CD | OR | α | Θ | CA |

| E-1 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 4° | 30° | 90° |

| E-2 | 25/1.0 | 33/1.3 | 99/3.9 | 4B/1.9 | 13/0.5 | 8° | 30° | 90° |

| E-3 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 11° | 30° | 90° |

| E-4 | 25/1.0 | 35/1.4 | 99/3.9 | 46/1.8 | 13/0.5 | 11° | 30° | 90° |

| E-5 | 30/1.2 | 38/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| E-6 | 30/1.2 | 3B/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

I-BPP: 70μm(μm/mil)

| Ingxenye NO. | WD | H | T | CD | OR | α | Φ | CA |

| F-1 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 8° | 30° | 90° |

| F-2 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 4° | 30′ | 90° |

| F-3 | 25/1.0 | 33/1.3 | 91/3.6 | 43/1.7 | 13/0.5 | 11° | 30′ | 90° |

I-BPP: 60μm(μm/mil)

| Ingxenye NO. | WD | H | T | CD | OR | α | Φ | CA |

| G-1 | 23/0.9 | 28/1.1 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |

| G-2 | 25/1.0 | 30/1.2 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |