Njengamanje, imboni yokucubungula imishini yaseShayina ithuthuka ngokushesha, futhi ezinye izinto okunzima ukuzisika zisetshenziswa kakhulu embonini yezinto ezibonakalayo kanye nemboni yemishini yokunemba.Ukuze sihlangabezane nezidingo zokuthuthukiswa kwemboni yesimanje yokucubungula imishini, sidinga ukusebenzisa amathuluzi athile anamandla aphezulu kanye nokuqina okuhle.Ngakho-ke, amathuluzi wezinto eziqinile asetshenziswa kancane kancane embonini yokucubungula imishini.Lesi sihloko sigxile ekusetshenzisweni kwamathuluzi wezinto eziqinile ekwenzeni imishini ngokubheka ukuthuthukiswa kwamathuluzi wezinto eziqinile, ukuze kuhlinzekwe ireferensi ehlangene kubangani abasembonini efanayo.

Ngokuthuthuka okusheshayo kobuchwepheshe besimanje bokukhiqiza kanye nokuncintisana kwemakethe okushubile, izidingo zemboni yokukhiqiza imishini yezingxenye zemishini yomshini nazo ziyakhula, ikakhulukazi ekusebenzeni kwesakhiwo sezingxenye zemishini.Ngakho-ke, izinto ezintsha ezinezakhiwo ezihlukahlukene ziye zavela kancane kancane emphakathini.Lezi zinto ezintsha azigcini nje ngokubeka inselele enkulu kumathuluzi endabuko okwenza imishini, kodwa futhi kunzima kakhulu ukuzicubungula.Ngalesi sikhathi, amathuluzi okusika athuthukile abe yisihluthulelo sokuthuthukiswa kwemboni yokucubungula imishini, futhi amathuluzi wezinto eziqinile ngokungangabazeki asetshenziswe ekucutshungulweni kwemishini yesimanje.

1. Umlando wokuthuthuka wamathuluzi wezinto eziqinile

Ngawo-1950, ososayensi baseMelika bathatha idayimane lokwenziwa, ibhondi, ne-boron carbide powder njengezinto ezingavuthiwe, basabela ngaphansi kwezinga lokushisa eliphezulu nokucindezela, kanye ne-sintered polycrystalline block njengento eyinhloko yethuluzi.Ngemuva kweminyaka yawo-1970, abantu kancane kancane bathuthukisa izinto zeshidi eziyinhlanganisela, ezikhiqizwa ngokuhlanganisa idayimane ne-carbide enosimende, noma i-boron nitride kanye ne-carbide enosimende.Kulobu buchwepheshe, i-carbide enosimende ithathwa njenge-substrate, futhi ungqimba lwedayimane lwakhiwe ebusweni be-substrate ngokucindezela noma ukucwilisa.Idayimane licishe libe ngu-0.5 kuya ku-1 mm ubukhulu.Izinto ezinjalo azikwazi nje ukuthuthukisa ukumelana nokugoba kwezinto, kodwa futhi zixazulule ngokuphumelelayo inkinga yokuthi izinto zendabuko akulula ukuzishisela.Lokhu kukhuthaze ithuluzi lezinto eziqinile ukungena esigabeni sokufaka isicelo.

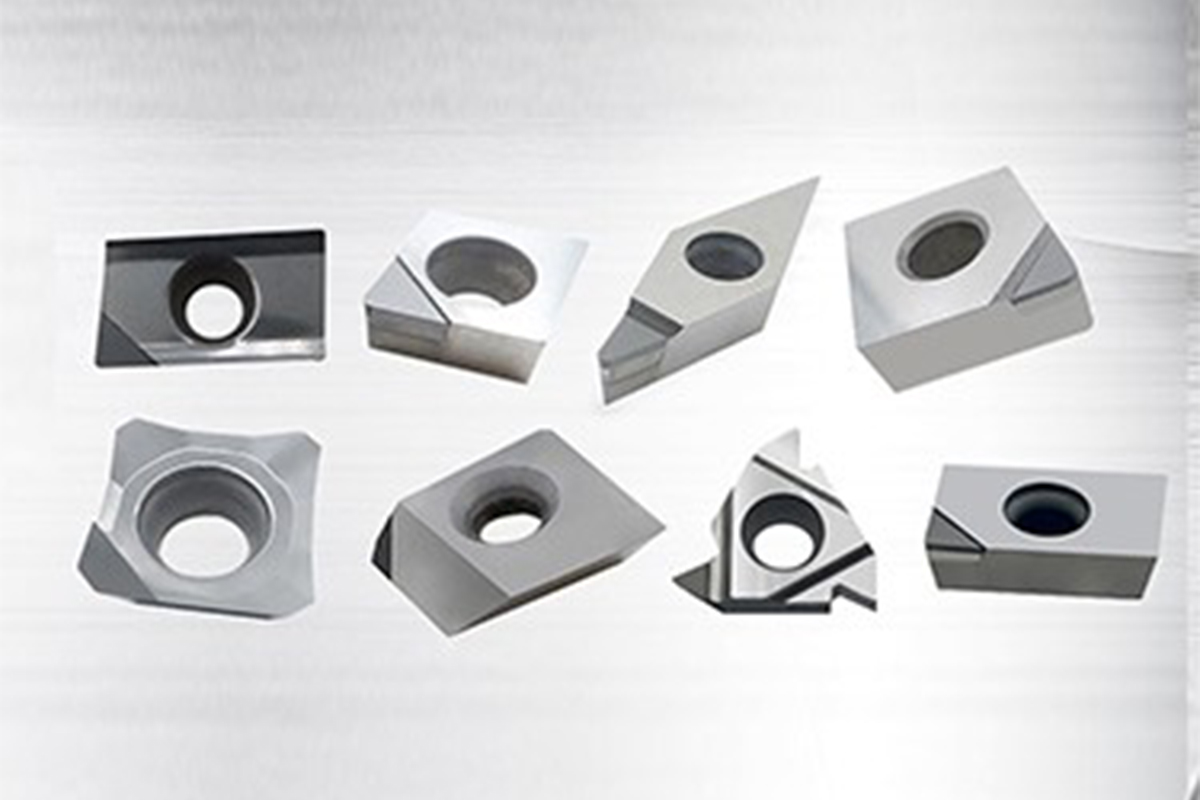

2. Ukusetshenziswa kwamathuluzi ezinto eziqinile ekwenzeni imishini

(1) Ukusetshenziswa kwamathuluzi edayimane elilodwa lekristalu

Idayimane lekristalu elilodwa livame ukuhlukaniswa ngedayimane lokwenziwa kanye nedayimane lemvelo.Ngokuvamile, uma kusetshenziswa idayimane lekristalu elilodwa ukwenza ithuluzi, kuyadingeka ukukhetha idayimane elinosayizi wezinhlayiyana ezinkulu, isisindo esikhulu kuno-0.1 g nobude bobubanzi obukhulu kuno-3 mm.Njengamanje, idayimane lemvelo liyinto enzima kakhulu kumaminerali.Ayinayo nje ukumelana nokugqoka okuhle, kodwa futhi ithuluzi elenziwe ngalo libukhali kakhulu.Ngesikhathi esifanayo, inokumelana nokunamathela okuphezulu kanye ne-conductivity ephansi yokushisa.Ithuluzi elicutshunguliwe libushelelezi futhi lisezingeni elihle.Ngesikhathi esifanayo, ithuluzi elenziwe ngedayimane lemvelo linokuqina okuhle kakhulu nempilo ende yesevisi.Ngaphezu kwalokho, lapho usika isikhathi eside, ngeke kuthinte ukucutshungulwa kwezingxenye.I-conductivity ephansi yokushisa ephansi ingaba nomthelela omuhle ekuvimbeleni ukuguquguquka kwezingxenye.

Idayimane lemvelo linezinzuzo eziningi.Nakuba lezi zinzuzo zibiza kakhulu, zingahlangabezana nezidingo zemisebenzi eminingi yokusika ngokunemba okuphezulu futhi zisetshenziswa kabanzi ekusikeni okunembayo kanye nokusika okunembe kakhulu.Njengokubonisa izibuko ezisebenzisa ama-athomu nobunye ubuchwepheshe obuthuthukisiwe, kanye nama-gyroscopes okuzulazula phansi asetshenziswa emicibisholo ecitshwayo noma amarokhethi, kanye nezinye izingxenye zewashi, izesekeli zensimbi, njll., busebenzise lobu buchwepheshe.

(2) Ukusetshenziswa kwamathuluzi edayimane e-polycrystalline

Idayimane le-Polycrystalline livame ukubizwa nge-sintered diamond.Ukusetshenziswa kwedayimane le-polycrystalline ngezinsimbi ezifana ne-cobalt, ngokusebenzisa izinga lokushisa eliphezulu nezimo zokucindezela okuphezulu, kuzokwenza i-polycrystalline eningi ye-diamond eyodwa ye-crystal powder ibe yinto eyodwa, ngaleyo ndlela yakhe ithuluzi le-polycrystalline.Ukuqina kwedayimane le-polycrystalline kungaphansi kokwedayimane lemvelo.Kodwa-ke, kwakhiwa izinhlobonhlobo ze-diamond powder, futhi akukho cala lokuthi izindiza ze-crystal ezahlukene zinamandla ahlukene nobulukhuni.Lapho usika, umkhawulo wokusika owenziwe ngedayimane le-polycrystalline unokumelana okuphezulu kakhulu nokulimala kwengozi nokumelana okuhle kokugqoka.Ingakwazi ukugcina umkhawulo wokusika ubukhali isikhathi eside uma kuqhathaniswa.Ngesikhathi esifanayo, ingasebenzisa isivinini sokusika esisheshayo lapho ikhiqiza.Uma kuqhathaniswa namathuluzi e-WC enosimende we-carbide, amathuluzi edayimane e-polycrystalline anokuphila kwesevisi okude, ukufinyelela okulula ezintweni zokwenziwa kanye namanani aphansi.

(3) Ukusetshenziswa kwedayimane le-CVD

Ithuluzi ledayimane le-CVD licutshungulwa ngaphansi kwengcindezi ephansi, okuwumehluko omkhulu kakhulu kubuchwepheshe be-PSC bendabuko kanye nobuchwepheshe be-PDC.Idayimane le-CVD aliqukethe noma iyiphi ingxenye ye-catalyst.Nakuba lifana nedayimane lemvelo kwezinye izakhiwo, lisafana nedayimane le-polycrystalline ezintweni ezisetshenziswayo, okungukuthi, izinhlamvu zokubunjwa azihlelwanga kahle, ukuntuleka kwe-brittle cleavage surface, futhi zinezakhiwo ezifanayo phakathi kwezindawo.Uma kuqhathaniswa namathuluzi enziwe ubuchwepheshe bendabuko, amathuluzi enziwe ubuchwepheshe bedayimane be-CVD anezinzuzo eziningi, njengokuma kwethuluzi eliyinkimbinkimbi, izindleko zokukhiqiza eziphansi, nama-blade amaningi ensingo efanayo.

(4) Ukusetshenziswa kwe-polycrystalline cubic boron nitride

I-Polycrystalline cubic boron nitride (PCBN) iyithuluzi elivamile lezinto eziqinile, elisetshenziswa kabanzi ekukhiqizeni imishini.Ithuluzi elenziwe ngalobu buchwepheshe linobunzima obuhle kakhulu nokumelana nokugqoka.Ngeke isetshenziswe kuphela emazingeni okushisa aphakeme kakhulu, kodwa futhi inokumelana nokugqwala okuhle kakhulu kanye ne-thermal conductivity.Uma kuqhathaniswa namathuluzi e-PCD ne-PDC, amathuluzi e-polycrystalline cubic boron nitride asengaphansi kokumelana nokugqoka, kodwa angasetshenziswa ngokujwayelekile ku-1200 ℃ futhi angamelana nokugqwala okuthile kwamakhemikhali!

Njengamanje, i-polycrystalline cubic boron nitride isetshenziswa kakhulu ekukhiqizeni izimoto, njengezinjini zezimoto, ama-transmission shafts, nama-brake disc.Ngaphezu kwalokho, cishe ingxenye eyodwa kwesihlanu yokucubungula imishini esindayo nayo isebenzisa lobu buchwepheshe.Eminyakeni yamuva, ngokuthuthukiswa kobuchwepheshe bekhompiyutha kanye nobuchwepheshe bethuluzi lomshini we-CNC, ukusetshenziswa kwe-polycrystalline cubic boron nitride kuye kwanda kakhulu, futhi ngokusetshenziswa kwemiqondo ethuthukisiwe yomshini njengokusika ngesivinini esikhulu, ukujika esikhundleni sokugaya, ithuluzi. impahla ye-polycrystalline cubic boron nitride ithuthuke kancane kancane yaba into ebalulekile ekucubungulweni kwesimanjemanje.

3. Isifinyezo

Ukusetshenziswa kwamathuluzi ezinto eziqinile ekwenzeni imishini akuthuthukisi nje kuphela ikhwalithi nokusebenza kahle komshini, kodwa futhi kudlala indima ebalulekile ekuthuthukiseni imboni yokucubungula imishini.Ngakho-ke, ukuze kuthuthukiswe ukuthuthukiswa kwemboni yokucubungula imishini, kuyadingeka ukuqinisa ngokuqhubekayo ucwaningo lwamathuluzi wezinto eziqinile, ukuqonda ngokugcwele ulwazi oluhlobene namathuluzi wezinto eziqinile, nokuqinisa umkhuba wokufaka isicelo, hhayi nje ukuthuthukisa ikhwalithi ye-hardware. abasebenzi, kodwa futhi nokuqinisa ukusetshenziswa kwesayensi nobuchwepheshe ekuthuthukiseni amathuluzi wezinto eziqinile, ukuze kubonakale ukuthuthukiswa kwe-leapfrog yemboni yokucubungula imishini.

Isikhathi sokuthumela: Jun-03-2019