T-Slot Milling Cutteriwukukhiqiza nokucutshungulwa okuphrofeshinali kwama-hard milling cutter amise okwe-T kuma-countertops emishini eyimishini ehlukahlukene noma ezinye izakhiwo.Ngaphandle kokucaciswa namamodeli, azikho izigaba eziningi zabasiki be-slot milling cutter.Ngokombono wesakhiwo, zingahlukaniswa zibe izisiki eziqondile ze-shank slot kanye nabasiki be-conical shank slot milling.Ngokombono wezinto ezibonakalayo, zingahlukaniswa zibe abasiki be-carbide T-slot milling cutter kanye nabasiki be-carbide T-slot milling.

Inketho yokuqala ilula kakhulu, okuwukukhetha ukuthi usebenzise isibambo esiqondile noma i-T-shape ngokusekelwe kumodeli yomuntu siqu noma ubukhulu bethuluzi elikhethekile.

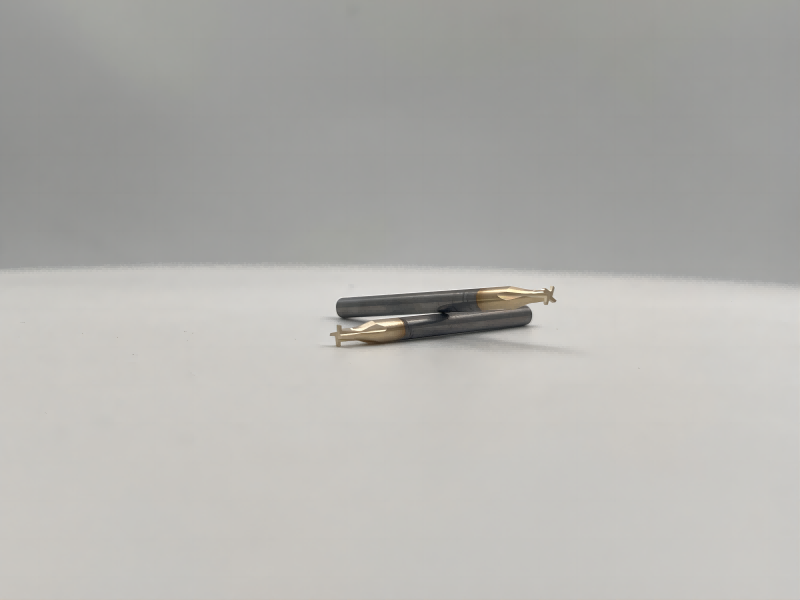

Kushumekiwecarbide T-slot milling umsiki, Nakuba kuyi-carbide, ibhekisela ku-blade encane efakwe phezulu kwe-blade emise okwe-T, ngamanye amazwi, i-blade phezulu kwekhanda i-carbide,I-collet nezinye izingxenye zonke zenziwe ngezinto zensimbi yasentwasahlobo. , futhi lolu hlobo lwesikimu sokuklama lusebenzisa ngokugcwele isici sokusebenzisa kuphela umkhawulo wokusika wesisekelo sethuluzi lokusika.Ngakho-ke, ukusebenzisa ukushumeka kwe-carbide engxenyeni enqenqemeni kungasindisa ngokunengqondo izindleko eziningi, futhi ngaphezu kwalokho, akulimazi umsebenzi ojwayelekile we-milling cutter, okuyindlela ewusizo kakhulu.

Ngakho-ke abanye abantu bangase bacabange, khona-ke wonke umuntu ubengeke akhethe umsiki ogcwele wokugaya i-carbide.Eqinisweni, ubukhona bunengqondo, Nakuba umsiki wokugaya omise okwe-T oshumekwe kuma-carbides unezinzuzo eziphawulekayo ngokwamanani, uma kuqhathaniswa nama-carbides agcwele, unobubi obubalulekile, okuwubunzima bokunemba.Njengoba ingxenye ye-blade ishumekiwe, ukuphambuka okuhlukahlukene akunakugwenywa.Ngakho-ke, uma ukunemba okucaciswe kumsele omise okwe-T womkhiqizo wakho wokusebenza noma okomshini wokusebenza kuphezulu kakhulu, kuyadingeka ukuthi ukhethe umsiki ogcwele we-carbide omise okwe-T.

Ngikholwa ukuthi ususitholile isimo sokukhetha umsiki wensimbi omise okwe-T.Empeleni kulula kakhulu ukuyisebenzisa.Lapho ukhiqiza futhi ucubungula izingcezu zokusebenza zomkhiqizo ezinemba okuphezulu, qiniseka ukuthi ukhetha i-milling cutter emise okwe-T ukuze uhlangabezane nezidingo zokucubungula.Ngokuvamile, kuma-workpieces womkhiqizo anezidingo ezinembayo eziphansi, isisiki sokugaya esimise okwe-T singakhethwa ngokufanelekile.

Isikhathi sokuthumela: Jun-26-2023