1.Cutting amathuluzi impahla

Izinto ezisetshenziswayo ezijwayelekile ekugayweni kwamathuluzi zifaka: insimbi enesivinini esikhulu, insimbi eyimpushana enesivinini esikhulu, i-carbide enosimende, i-PCD, i-CBN, i-cermet nezinye izinto eziqinile.Amathuluzi ensimbi anesivinini esiphezulu abukhali futhi anokuqina okuhle, kuyilapho amathuluzi e-carbide anobulukhuni obuphezulu kodwa aqinile.Ukuminyana kwamathuluzi e-carbide enosimende kuphezulu kakhulu kunamathuluzi ensimbi anesivinini esikhulu.Lezi zinto ezimbili ziyizinto eziyinhloko zama-drill bits, ama-reamer, ama-milling cutters kanye nompompi.Ukusebenza kwensimbi eyimpushana yensimbi enesivinini esikhulu kuphakathi kwezinto ezimbili ezingenhla, futhi isetshenziselwa ikakhulukazi ukukhiqiza isisiki sokugaya esimahhadla nokumpompi.

Amathuluzi ensimbi anesivinini esikhulu awazwelani nokushayisana ngenxa yokuqina kwawo okuhle.Kodwa-ke, amathuluzi e-carbide enosimende anobulukhuni obuphezulu kanye nokuqina, azwela kakhulu lapho kushayisana, futhi unqenqema kulula ukugxuma.Ngakho-ke, ohlelweni lokugaya, kuyadingeka ukuthi uqaphele kakhulu mayelana nokusebenza nokubekwa kwamathuluzi e-carbide enosimende ukuvimbela ukungqubuzana phakathi kwamathuluzi noma ukuwa kwamathuluzi.

Ngenxa yokuthi ukunemba kwamathuluzi ensimbi anesivinini esikhulu kuphansi uma kuqhathaniswa, izidingo zawo zokugaya aziphezulu, futhi amanani awo awaphezulu, abakhiqizi abaningi bazibekela ezabo izinkundla zokucobelelana ngolwazi ukuze bawagaye.Kodwa-ke, amathuluzi e-carbide enosimende ngokuvamile adinga ukuthunyelwa esikhungweni sokugaya sochwepheshe ukuze kugaywe.Ngokwezibalo zezikhungo eziningi zokugaya amathuluzi, ngaphezu kwe-80% yamathuluzi athunyelwe ukukhanda amathuluzi e-carbide enosimende.

2. Ithuluzi lokusika igrinder

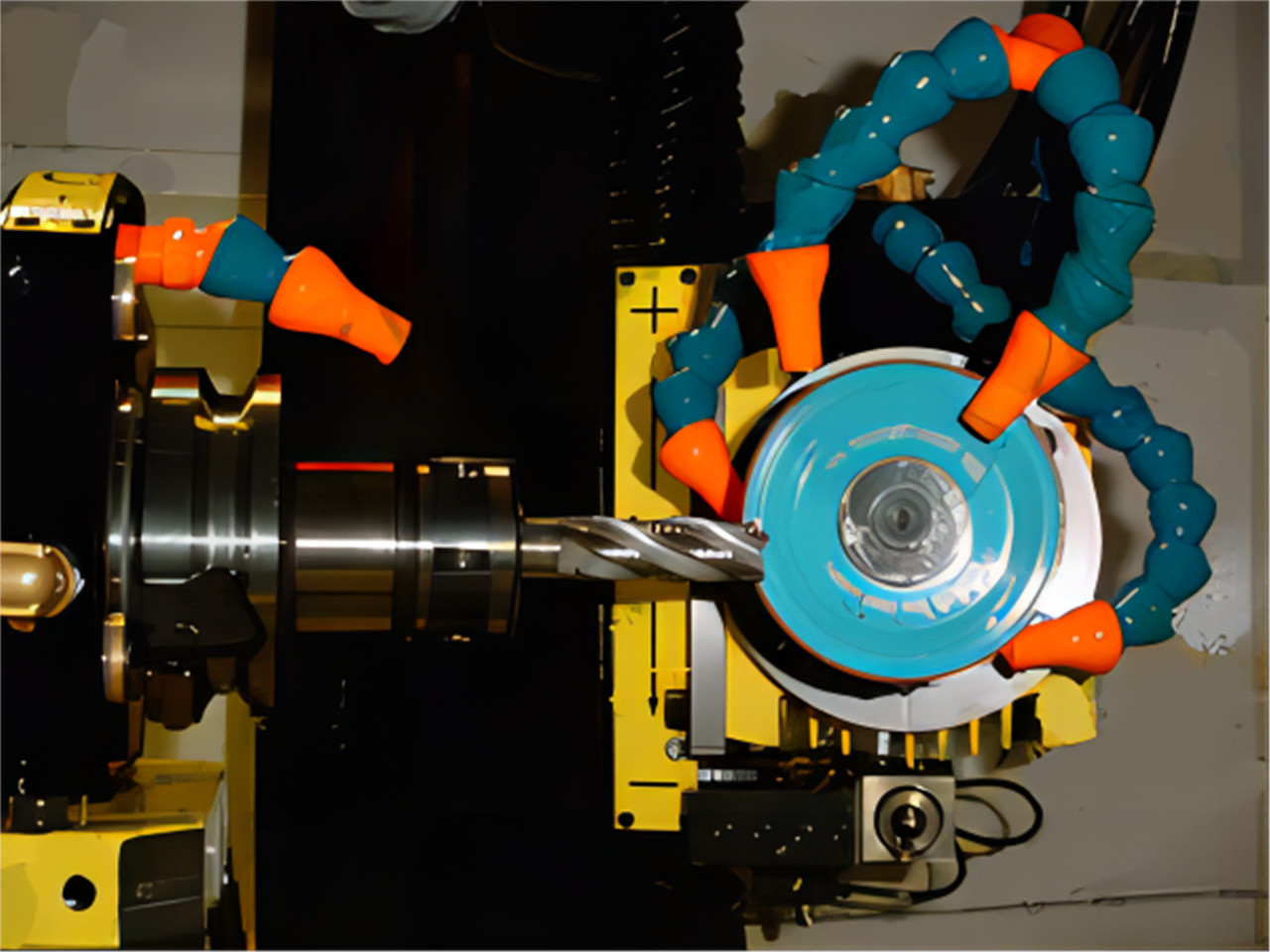

Ngoba impahla yamathuluzi inzima kakhulu, ingashintshwa kuphela ngokugaya.Izigayi zamathuluzi ezivamile ezisetshenziswa ekwenzeni amathuluzi nasekugayeni zihlanganisa okulandelayo:

(1).Umshini wokugaya: ukugaya i-groove noma ngemuva kwezinsimbi zokubhoboza, izigayo zokugcina namanye amathuluzi.

(2).I-Angle grinder: ukugaya i-engeli ephezulu yekholi (noma i-eccentric back angle) yebhithi yokubhoboza.

(3) Umshini wokusika: Lungisa unqenqema oluseceleni lwebhithi yokubhoboza.

(4).Ithuluzi lokugaya ithuluzi: ukugaya indilinga yangaphandle, igroove, emuva, i-engeli ephezulu, unqenqema oluphambene, indiza, ubuso bangaphambili, njll. Ivame ukusetshenziselwa amathuluzi anenani elincane kanye nesimo esiyinkimbinkimbi.

(5).Umshini wokugaya we-CNC: ngokuvamile ukuxhumana kwama-eksisi amahlanu, nemisebenzi enqunywe isofthiwe.Ngokuvamile isetshenziselwa amathuluzi okugaya anenani elikhulu kanye nezidingo zokunemba okuphezulu, kodwa okungeyona inkimbinkimbi, njengezinsimbi zokubhoboza, izigayo, ama-reamers, njll. Abahlinzeki abakhulu balezi zigayo bavela eJalimane, e-Switzerland, e-United States, e-Australia nase-Japan. .

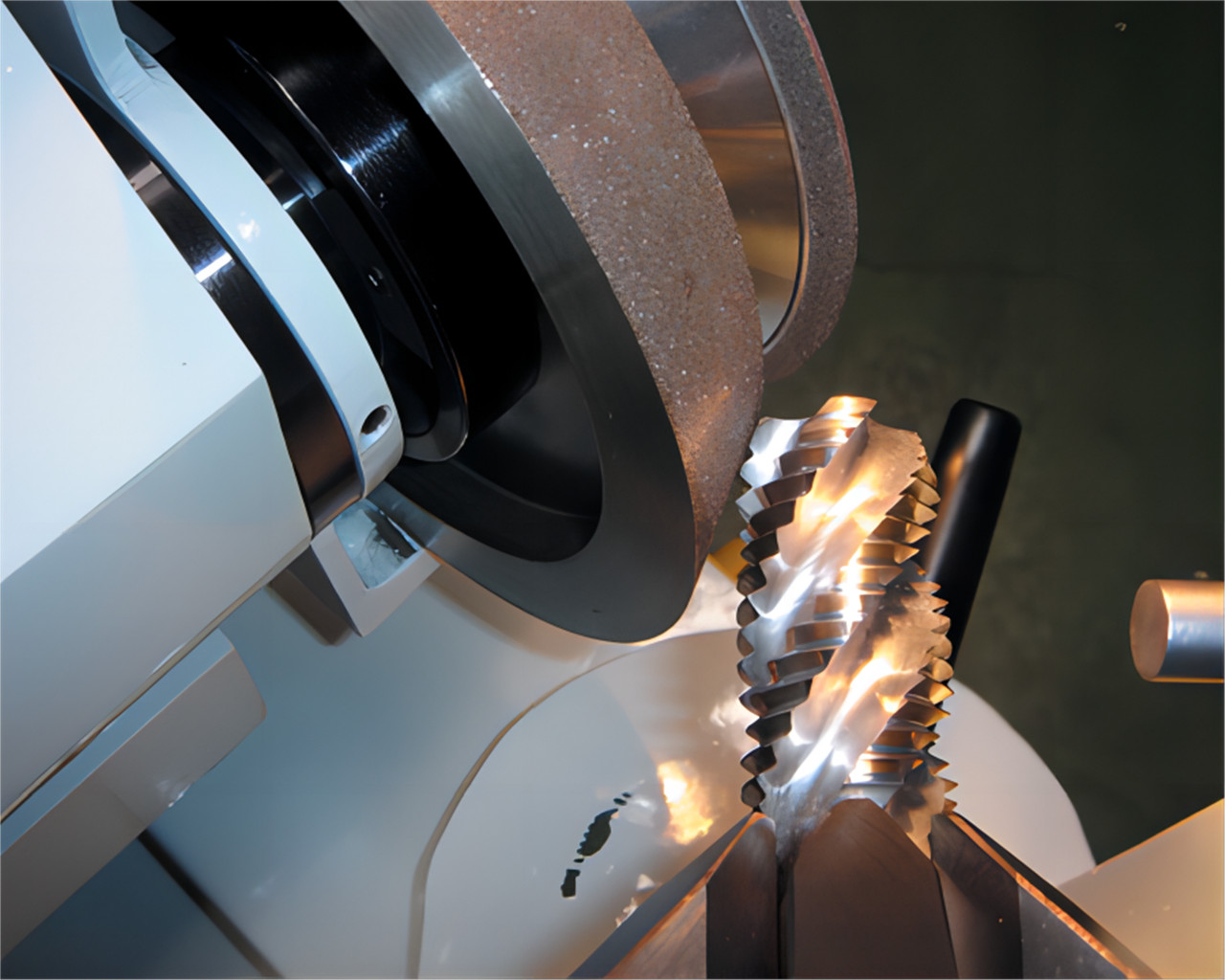

3.Isondo lokugaya

(1).Izinhlayiya ezihlabayo

I-grinding wheel abrasive izinhlayiya zezinto ezihlukahlukene zifanelekile ukugaya amathuluzi wezinto ezahlukene.Izingxenye ezihlukene zethuluzi zidinga amasayizi ahlukene abrasive ukuze kuqinisekiswe inhlanganisela engcono kakhulu yokuvikela unqenqema nokusebenza kahle kokucubungula.

I-Alumina: isetshenziselwa ukugaya amathuluzi e-HSS.Isondo lokugaya lishibhile futhi kulula ukuguqulwa libe yizimo ezihlukene zokugaya amathuluzi ayinkimbinkimbi (corundum).

I-Silicon carbide: isetshenziselwa ukulungisa isondo lokugaya le-CBN nesondo lokugaya idayimane.

I-CBN (i-cubic boron carbide): isetshenziselwa ukugaya amathuluzi e-HSS.Intengo ephezulu, kodwa ihlala isikhathi eside.

Emazweni omhlaba, isondo lokugaya limelelwa ngu-B, njenge-B107, lapho u-107 umele ubukhulu bezinhlayiya ezilumayo.

Idayimane: Isetshenziselwa ukugaya amathuluzi e-HM.Iyabiza kodwa ihlala isikhathi eside.

(2).Isimo

Ukuze kube lula ukugaya izingxenye ezahlukene zethuluzi, isondo lokugaya kufanele libe nezimo ezihlukene.Okuvame ukusetshenziswa kakhulu yilezi:

Isondo lokugaya elihambisanayo (1A1): i-engeli ephezulu yokugaya, ububanzi obungaphandle, emuva, njll.

Isondo lokugaya (12V9, 11V9): ukugaya i-spiral groove, unqenqema oluyinhloko nolusizo lwe-milling cutter, ukusika unqenqema oluvundlile, njll.

Ngemuva kokuthi isondo lokugaya selisetshenziswe isikhathi esithile, ukuma kwayo (kuhlanganise nendiza, i-angle kanye ne-fillet R) idinga ukulungiswa.Isondo lokugaya kufanele livame ukusebenzisa itshe lokuhlanza ukuze lisuse ama-chips agcwele phakathi kwezinhlamvu ezilumayo ukuze kuthuthukiswe ikhono lokugaya lesondo lokugaya.

4.Izinga lokugaya

Ukuthi kukhona isethi enhle yamazinga okugaya amathuluzi kuyindinganiso yokulinganisa ukuthi isikhungo sokugaya siwuchwepheshe.Ezingeni lokugaya, amapharamitha wobuchwepheshe onqenqema lokusika wamathuluzi ahlukene lapho kusikwa izinto ezahlukahlukene ngokuvamile acacisiwe, kufaka phakathi i-angle yokuthambekela, i-engeli ephezulu, i-angle yangaphambili, i-angle yangemuva, i-chamfer, i-chamfer namanye amapharamitha (kubhithi ye-carbide enosimende. , inqubo yokudlula onqenqemeni lokusika ibizwa ngokuthi "i-chamfer", futhi ububanzi be-chamfer buhlobene nezinto okufanele zisikwe, ngokuvamile phakathi kuka-0.03-0.5Mm no-0.25Mm. ibizwa ngokuthi "i-chamfer". Inkampani ngayinye yobungcweti inamazinga ayo okugaya afingqiwe ngokuhamba kweminyaka.

Umehluko phakathi kwe-HM bit ne-HSS bit:

Ibhithi ye-HSS: i-engeli ephezulu ngokuvamile iba ngamadigri angu-118, ngezinye izikhathi inkulu kuno-130 degrees;I-blade ibukhali;Izidingo zokunemba (umehluko wobude be-blade, i-symmetry, ukuphuma kwe-circumferential) ziphansi kakhulu.Kunezindlela eziningi zokulungisa i-blade evundlile.

I-HM bit: i-engeli ephezulu ngokuvamile i-140 degrees;Ama-slot drill aqondile ngokuvamile ama-degree angu-130, kanti ama-drill asemaphethelweni amathathu ngokuvamile ama-degree angu-150.I-blade ne-tip (enqenqemeni) ayibukhali futhi ngokuvamile idlula, noma ibizwa ngokuthi i-chamfer ne-chamfer;Kudinga ukunemba okuphezulu.I-blade evundlile ivamise ukusikwa ibe yi-S-shape ukuze kube lula ukuphuka kwe-chip.

I-engeli yangemuva: I-engeli yangemuva ye-blade ibaluleke kakhulu ethuluzini.Ikhona elingemuva likhulu kakhulu, futhi i-blade kulula ukugxuma futhi "ukugwaza";Uma i-angle yangemuva incane kakhulu, ukungqubuzana kuzoba kukhulu kakhulu futhi ukusika ngeke kube kuhle.

I-engeli yangemuva yethuluzi iyahlukahluka ngezinto ezizosikwa kanye nohlobo nobubanzi bethuluzi.Ngokuvamile, i-engeli yangemuva iyancipha ngokukhula kobubanzi bethuluzi.Ngaphezu kwalokho, uma izinto ezizonqunywa zilukhuni, i-angle yangemuva izoba yincane, ngaphandle kwalokho, i-angle yangemuva izoba nkulu.

5.Imishini yokuhlonza Amathuluzi Okusika

Amathuluzi okusika amathuluzi avame ukuhlukaniswa abe izigaba ezintathu: ithuluzi lokusetha ithuluzi, iprojektha kanye nethuluzi lokulinganisa lamathuluzi jikelele.Ithuluzi lokusetha ithuluzi lisetshenziselwa ngokuyinhloko ukulungiswa kwezilungiselelo zamathuluzi (ezifana nobude) bezinto zokusebenza ze-CNC ezifana nezikhungo zomshini, kanye nokuthola amapharamitha afana ne-engeli, irediyasi, ubude besinyathelo, njll;Umsebenzi weprojektha uphinde usetshenziswe ukuthola amapharamitha afana ne-engeli, irediyasi, ubude besinyathelo, njll. Nokho, okubili okungenhla akukwazi ukukala i-engeli yangemuva yethuluzi.Ithuluzi lokulinganisa ithuluzi lomhlaba wonke lingakala amapharamitha amaningi wejiyomethri wethuluzi, okuhlanganisa i-engeli yangemuva.

Ngakho-ke, isikhungo sokugaya amathuluzi ochwepheshe kufanele sifakwe ithuluzi lokulinganisa ithuluzi lomhlaba wonke.Kodwa-ke, bambalwa abahlinzeki bemishini enjalo, futhi kunemikhiqizo yaseJalimane neyesiFulentshi emakethe.

6.Uchwepheshe wokugaya

Izisetshenziswa ezingcono kakhulu zidinga abasebenzi abazosebenza, futhi ukuqeqeshwa kochwepheshe bokugaya ngokwemvelo kungenye yezixhumanisi ezibaluleke kakhulu.Ngenxa yomkhakha wokukhiqiza amathuluzi osalele emuva uma kuqhathaniswa e-China kanye nokushoda okukhulu kokuqeqeshwa kwemisebenzi yezandla nezobuchwepheshe, ukuqeqeshwa kochwepheshe bokugaya amathuluzi kungaxazululwa yibhizinisi ngokwalo.

7. Isiphetho

Ngemishini yokugaya, imishini yokuhlola nezinye izinto zehadiwe kanye namazinga okugaya, ochwepheshe bokugaya namanye ama-software, ukugaywa kwamathuluzi anembayo kungaqala.Ngenxa yobunkimbinkimbi bokusetshenziswa kwamathuluzi, isikhungo sokugaya esiphrofeshinali kufanele siguqule ngesikhathi uhlelo lokugaya ngokwendlela yokwehluleka kwethuluzi elizogaywa, futhi silandelele umthelela wokusetshenziswa wethuluzi.Isikhungo sokugaya amathuluzi esichwepheshile kufanele sihlale sifingqa isipiliyoni ukuze senze ukugaya ithuluzi kube ngcono futhi kube ngochwepheshe kakhulu!

Isikhathi sokuthumela: Feb-24-2023