Ngokuthuthuka kwesayensi nobuchwepheshe besimanje, izinto zokwakha zobunjiniyela ezikhulayo ezinobunzima obuphakeme ziyasetshenziswa, kuyilapho ubuchwepheshe bokuguqula bendabuko bungenalo ikhono noma abukwazi ukufeza ukucutshungulwa kwezinye izinto ezinobulukhuni obuphakeme nhlobo.I-carbide eboshwe, i-ceramics, i-PCBN nezinye izinto zamathuluzi aqinile zinobulukhuni bokushisa obuphezulu, ukumelana nokugqoka kanye nokuzinza kwe-thermochemical, okunikeza imfuneko eyisisekelo kakhulu yokusikwa kwezinto ezinobunzima obuphezulu, futhi bathole izinzuzo ezibalulekile ekukhiqizeni.Izinto ezisetshenziswa ithuluzi eliqinile kakhulu kanye nesakhiwo salo samathuluzi kanye nemingcele yejometri yizici eziyisisekelo zokubona ukuguquka okunzima.Ngakho-ke, indlela yokukhetha impahla yamathuluzi aqinile futhi uklame isakhiwo samathuluzi esiphusile kanye nemingcele yejiyomethri ibalulekile ukuze kuzuzwe ukuphenduka okuqinile okuzinzile!

(1) I-carbide enosimende eboshwe

Faka isendlalelo esisodwa noma ngaphezulu se-TiN, i-TiCN, i-TiAlN ne-Al3O2 enokumelana okuhle nokugqokwa kumathuluzi e-carbide enosimende anokuqina okuhle, futhi ukujiya kokumboza kungu-2-18 μ m.I-coating ngokuvamile ine-conductivity ephansi kakhulu yokushisa kune-substrate yamathuluzi kanye nezinto zokusebenza, okwenza buthaka umphumela wokushisa we-substrate yamathuluzi;Ngakolunye uhlangothi, kungathuthukisa ngokuphumelelayo ukungqubuzana nokunamathela ohlelweni lokusika futhi kunciphise isizukulwane sokusika ukushisa.

Nakuba ukugqoka kwe-PVD kukhombisa izinzuzo eziningi, ezinye izigqoko ezifana ne-Al2O3 nedayimane zivame ukusebenzisa ubuchwepheshe bokuhlanganisa i-CVD.I-Al2O3 iwuhlobo lokumboza olunokumelana nokushisa okuqinile nokumelana ne-oxidation, okungahlukanisa ukushisa okukhiqizwa ngokusika ethuluzini elithile.Ubuchwepheshe bokugqoka i-CVD bungakwazi futhi ukuhlanganisa izinzuzo zezingubo ezihlukahlukene ukuze kuzuzwe umphumela omuhle kakhulu wokusika futhi kuhlangabezane nezidingo zokusika.

Uma kuqhathaniswa namathuluzi e-carbide enosimende, amathuluzi e-carbide anosimende athuthuke kakhulu emandleni, ukuqina kanye nokumelana nokugqoka.Lapho uphendula ucezu lomsebenzi ngobulukhuni be-HRC45~55, i-carbide enosimende eshibhile ingabona ukuphenduka kwesivinini esikhulu.Eminyakeni yamuva, abanye abakhiqizi baye bathuthukisa ukusebenza kwamathuluzi ahlanganisiwe ngokuthuthukisa izinto zokugqoka nezinye izindlela.Isibonelo, abanye abakhiqizi e-United States nase-Japan basebenzisa okokunamathelayo kwe-Swiss AlTiN kanye nobuchwepheshe obusha obunelungelo lobunikazi bokunamathela ukuze bakhiqize izindwani ezinamekwe ezinobunzima obufinyelela ku-HV4500~4900, ezingasika insimbi yokufa ye-HRC47~58 ngesivinini esingu-498.56m/min. .Lapho izinga lokushisa eliguqukayo lifika ku-1500 ~ 1600 ° C, ubulukhuni abunciphi futhi abukhiqizi.Impilo yesevisi ye-blade iphindwe kane kune-blade evamile eboshwe, kuyilapho izindleko zingama-30% kuphela, futhi ukunamathela kuhle.

(2) I-Ceramicmaterial

Ngokuthuthuka okuqhubekayo kokubunjwa kwayo, ukwakheka kanye nenqubo yokucindezela, ikakhulukazi ukuthuthukiswa kwe-nanotechnology, izinto zamathuluzi e-ceramic zenza kube nokwenzeka ukuqinisa amathuluzi e-ceramic.Esikhathini esizayo esiseduze, izitsha zobumba zingase zibangele uguquko lwesithathu ekusikeni ngemva kwensimbi enesivinini esikhulu kanye ne-carbide enosimende.Amathuluzi e-Ceramic anezinzuzo zobulukhuni obuphezulu (HRA91~95), amandla aphezulu (amandla okugoba 750 ~ 1000MPa), ukumelana nokugqoka okuhle, ukuqina okuhle kwamakhemikhali, ukumelana okuhle kokunamathela, i-coefficient ephansi yokungqubuzana kanye nenani eliphansi.Akukhona lokho kuphela, amathuluzi e-ceramic abuye abe nobulukhuni bokushisa obuphezulu, obufinyelela ku-HRA80 ku-1200 ° C.

Ngesikhathi sokusika okuvamile, ithuluzi le-ceramic linokuqina okuphezulu kakhulu, futhi ijubane layo lokusika lingaba izikhathi ezingu-2 ~ 5 ngaphezu kwe-carbide enosimende.Ifaneleka ngokukhethekile ukukhanda izinto zokuqina okuphezulu, ukuqeda kanye nomshini wejubane eliphezulu.Ingakwazi ukusika insimbi eqinile ehlukahlukene nensimbi eqinile eqinile kuze kufike ku-HRC65.Okuvame ukusetshenziswa izitsha zobumba ezisekelwe ku-alumina, izitsha zobumba ezisekelwe ku-silicon nitride, ama-cermets nezitsha zobumba eziqinisiwe ze-whisker.

Amathuluzi e-ceramic asekelwe ku-alumina anokuqina okubomvu okuphezulu kune-carbide enosimende.Ngokuvamile, umkhawulo wokusika ngeke ukhiqize ukuguqulwa kwepulasitiki ngaphansi kwezimo zokusika ngesivinini esikhulu, kodwa amandla nokuqina kwawo kuphansi kakhulu.Ukuze kuthuthukiswe ukuqina kwayo kanye nokumelana nomthelela, i-ZrO noma i-TiC nengxube ye-TiN ingangezwa.Enye indlela yokwengeza amadevu ensimbi noma e-silicon carbide.Ngaphezu kokuqina okubomvu okuphezulu, izitsha zobumba ezisekelwe ku-silicon nitride nazo zinokuqina okuhle.Uma kuqhathaniswa nezitsha zobumba ezenziwe nge-alumina, okubi kwayo ukuthi kulula ukukhiqiza ukushisa okuphezulu kokusabalalisa lapho kwenziwa insimbi, okwenza kube nzima ukugqokwa kwamathuluzi.Izitsha zobumba ezisekelwe ku-silicon nitride zisetshenziselwa kakhulu ukuphenduka nokugaya insimbi empunga.

I-Cermet iwuhlobo lwezinto ezisekelwe ku-carbide, lapho i-TiC iyisigaba esinzima esiyinhloko (0.5-2 μm) Zihlanganiswe nezibophezelo ze-Co noma ze-Ti futhi zifana namathuluzi e-carbide kasimende, kodwa anobudlelwane obuphansi, ukungqubuzana okuhle nokuhle. ukumelana nokugqoka.Ingakwazi ukumelana nezinga lokushisa eliphakeme lokusika kune-carbide evamile kasimende, kodwa ayinakho ukumelana nomthelela we-carbide enosimende, ukuqina ngesikhathi sokusika okunzima kanye namandla ngesivinini esiphansi kanye nokudla okukhulu.

(3) I-Cubic boron nitride (CBN)

I-CBN ingeyesibili ngemva kwedayimane ngobulukhuni nokumelana nokugqoka, futhi inokuqina okuhle kakhulu kwezinga lokushisa eliphezulu.Uma kuqhathaniswa ne-ceramics, ukumelana nokushisa kwayo nokuzinza kwamakhemikhali kumpofu kancane, kodwa amandla ayo okuthinta nokusebenza okuphikisana nokuchotshozwa kungcono.Isebenza kabanzi ekusikeni kwensimbi eqinile (HRC ≥ 50), i-pearlitic grey cast iron, i-cast cast iron kanye ne-superalloy.Uma kuqhathaniswa namathuluzi e-carbide enosimende, ijubane layo lokusika linganyuswa nge-oda elilodwa lobukhulu.

Ithuluzi elihlanganisiwe le-polycrystalline cubic boron nitride (PCBN) elinokuqukethwe okuphezulu kwe-CBN linokuqina okuphezulu, ukumelana nokugqokwa okuhle, amandla acindezelayo aphezulu kanye nokuqina komthelela omuhle.Ukungalungi kwayo ukungazinzi kahle kokushisa kanye nokungabi namakhemikhali aphansi.Ilungele ukusika ama-alloys angangeni ekushiseni, insimbi eyinsimbi kanye nezinsimbi ezisekelwe ensimbi.Okuqukethwe kwezinhlayiya ze-CBN kumathuluzi e-PCBN kuphansi, futhi ubulukhuni bamathuluzi e-PCBN asebenzisa i-ceramics njenge-binder buphansi, kodwa benza ukuqina okuphansi kokushisa kanye ne-inertia yamakhemikhali ephansi yento yangaphambili, futhi ifanele ukusika insimbi eqinile.

Lapho usika insimbi empunga nensimbi eqinile, ithuluzi le-ceramic noma ithuluzi le-CBN lingakhethwa.Ngalesi sizathu, izindleko-inzuzo kanye nokuhlaziywa kwekhwalithi yokucubungula kufanele kwenziwe ukuze kunqunywe ukuthi iyiphi okumele ikhethwe.Uma ubulukhuni bokusika buphansi kune-HRC60 futhi kwamukelwa isilinganiso esincane sokuphakelayo, ithuluzi le-ceramic liyisinqumo esingcono.Amathuluzi e-PCBN afanele ukusika izingcezu zokusebenza ezinobulukhuni obungaphezu kwe-HRC60, ikakhulukazi ukumishini okuzenzakalelayo kanye nomshini wokunemba okuphezulu.Ngaphezu kwalokho, ingcindezi eyinsalela endaweni yokusebenza ngemuva kokusika ngethuluzi le-PCBN nayo izinzile kunaleyo enethuluzi le-ceramic ngaphansi kwesimo sokugqokwa kweflank efanayo.

Uma usebenzisa ithuluzi le-PCBN ukomisa insimbi eqinile, lezi zimiso ezilandelayo kufanele futhi zilandelwe: khetha ukujula okukhulu kokusika ngangokunokwenzeka ngaphansi kwesimo sokuthi ukuqina kwethuluzi lomshini kuvumela, ukuze ukushisa okukhiqizwa endaweni yokusika kungathambisa. insimbi engaphambili konqenqema endaweni, enganciphisa ngempumelelo ukugqokwa kwethuluzi le-PCBN.Ngaphezu kwalokho, uma usebenzisa ukujula okuncane kokusika, kufanele futhi kucatshangelwe ukuthi ukungahambi kahle okushisayo kwethuluzi le-PCBN kungenza ukushisa endaweni yokusika sekwephuzile kakhulu ukusabalalisa, futhi indawo yokugunda nayo ingakhiqiza umphumela ocacile wokuthambisa insimbi, Yehlisa ukugqoka onqenqemeni.

2. Isakhiwo se-blade kanye nemingcele yejometri yamathuluzi anzima kakhulu

Ukuzimisela okunengqondo kokuma kanye nemingcele yejometri yethuluzi kubaluleke kakhulu ukunikeza ukudlala okugcwele ekusebenzeni kokusika kwethuluzi.Mayelana namandla ethuluzi, amandla ephuzu lethuluzi lomumo we-blade ohlukahlukene ukusuka phezulu kuye phansi: nxazonke, 100 ° idayimane, isikwele, idayimane elingu-80 °, unxantathu, idayimane elingu-55 °, idayimane elingu-35 °.Ngemuva kokukhethwa kwe-blade, i-blade shape enamandla kakhulu izokhethwa.Ama-blade aphendukayo aqinile kufanele nawo akhethwe abe makhudlwana ngangokunokwenzeka, futhi ukukhanda okungalungile kufanele kwenziwe ngama-arc radius blades ayindilinga namakhulu.I-tip arc radius icishe ibe ngu-0.8 uma iqeda μ Cishe m.

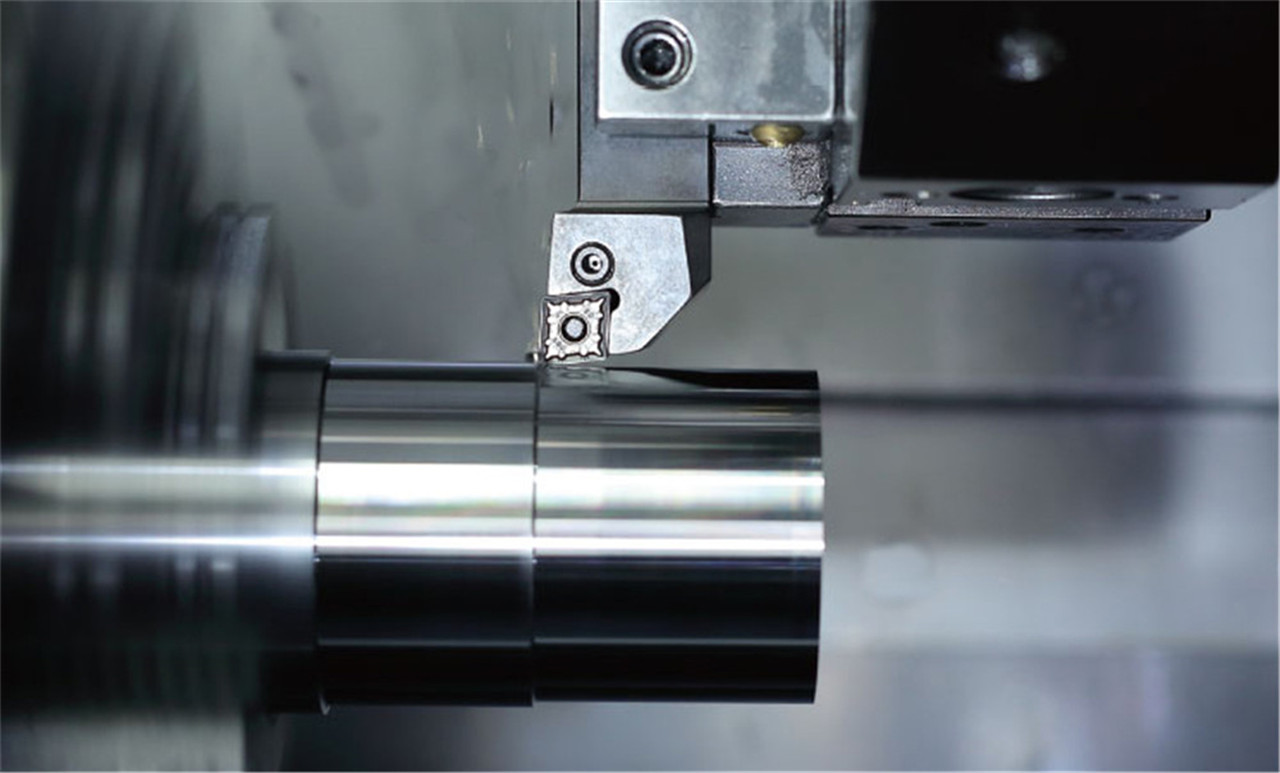

Ama-chips ensimbi aqinile angamaribhoni abomvu nathambile, anobukhazikhazi obukhulu, aphuka kalula futhi awabophi.Indawo yokusika insimbi eqinile isezingeni eliphezulu futhi ngokuvamile ayikhiqizi ukuqoqwa kwe-chip, kodwa amandla okusika makhulu, ikakhulukazi amandla okusika ama-radial makhulu kunamandla amakhulu okusika.Ngakho-ke, ithuluzi kufanele lisebenzise i-engeli yangaphambili engalungile (hamba ≥ - 5 °) kanye ne-engeli enkulu yangemuva (ao=10°~15°).I-engeli enkulu yokuchezuka incike ekuqineni kwethuluzi lomshini, ngokuvamile elingu-45 °~60 °, ukuze kuncishiswe ukuxoxa kwengcezu yokusebenza nethuluzi.

Isikhathi sokuthumela: Feb-24-2023