Uyini umehluko nomehluko phakathi kwabasiki be-HSS bokugaya kanye nabasiki be-Carbide ngokwezinto zokwakha, ukwakheka, nokusebenza?Yiziphi izimo zokwenza imishini lapho amathuluzi e-HSS kufanele asetshenziswe kuzo, futhi yiziphi izimo lapho amathuluzi eCarbide kufanele asetshenziswe khona?

1. Umehluko phakathi kwe-HSS End Mill ne-Tungsten Carbide End Mill

1. Umehluko ezintweni.

I-HSS End Mill yenziwe ngezinsimbi zensimbi ezinesivinini esikhulu, ngokuvamile ezenziwe ngezinto ze-M42, ezinokuqukethwe kwe-vanadium okungengaphezu kuka-1% kanye ne-cobalt engu-8%.

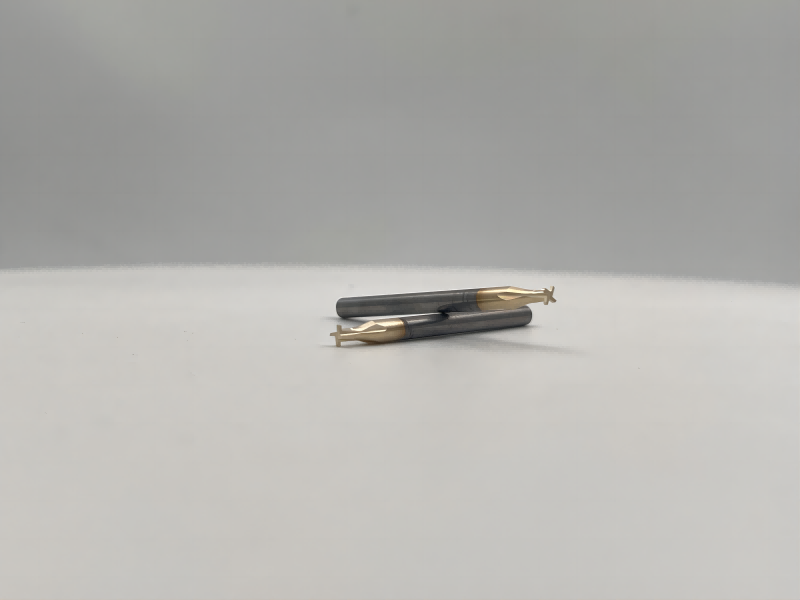

I-Carbide End Mill iyithuluzi CNC eyenziwe Tungsten Carbide.

2. Umehluko ekusebenzeni kokucubungula.

Amathuluzi okusika e-HSS anobunzima bezinga lokushisa kwegumbi obungu-62-70HRC, kuyilapho amathuluzi okusika i-carbide anobunzima bezinga lokushisa obungu-89-94HRC.Ukumelana nokushisa kwendawo yamathuluzi kufinyelela ku-1000 ℃, futhi ijubane lokusika le-carbide lingakhuphuka ngo-50-100% uma liqhathaniswa ne-HSS.Ukuqina kwethuluzi kungathuthukiswa izikhathi ezingama-2-10;Uma kuqhathaniswa namathuluzi wokusika we-HSS, amathuluzi okusika i-carbide afaneleka kakhulu ekucubunguleni okuhamba ngesivinini esikhulu, okusebenzayo, kanye nezinga eliphezulu lokushisa.

amathuluzi okusika i-carbideIphuzu elincibilikayo eliphakeme, ukuqina okuphezulu, imodulus enwebekayo ephezulu, ukuqina okuhle kwamakhemikhali kanye nokuzinza kokushisa.Ubulukhuni bayo, ukumelana nokugqoka kanye nokumelana nokushisa kungcono kakhulu kunamathuluzi okusika we-HSS.

Ukuqina: Ithuluzi le-Carbide 89~94HRC.Amathuluzi e-HSS 62-70HRC.

Ukumelana nokushisa: Amathuluzi eCarbide ku-800-1000 ℃, amathuluzi e-HSS ku-600-650 ℃.

Ukumelana nokugqoka: Ukumelana nokugqokwa kwamathuluzi eCarbide izikhathi eziyi-15-20 kunamathuluzi e-HSS.

Isivinini sokusika: Ijubane lethuluzi leCarbide liphindwe ka-4-10 kunethuluzi le-HSS.

2. Kuyoba nini abasiki be-HSS noI-Carbide milling cutterskusetshenziswe?

Akuzona zonke izimo zokucubungula ezidinga ukusetshenziswa kwe-Carbide milling cutters, njengoba ukulawulwa kwezindleko zenqubo ngayinye yokucubungula kuyahlukahluka, futhi amathuluzi ahlukahlukene okusika angasetshenziswa ngokuguquguqukayo.

Lapho ubulukhuni bemishini buphansi, izidingo zokunemba kwemishini aziphezulu, futhi amathuluzi omshini osezingeni eliphansi asetshenziswa, inani lemikhiqizo lincane, futhi inzuzo iphansi, amathuluzi okusika we-HSS angasetshenziswa.Ngisho nakwezinye izinto okunzima ukuzenza umshini, amathuluzi e-HSS nawo angaba nekhono, kodwa ijubane lawo lokusika, ukumelana nokugqoka, nokuqina kwawo akwanele.

Ngicabanga ukuthi ezimweni eziningi, ikakhulukazi ngesikhathi somshini wejubane eliphezulu, ophumelelayo, futhi omkhulu, kudingekile kakhulu ukusebenzisa amathuluzi okusika i-carbide, ngisho namathuluzi e-ceramic nedayimane: izindleko eziphezulu zethuluzi elilodwa akusho ukuthi izindleko eziphezulu zokucubungula. ;Ezimweni eziningi, ukusebenzisa amathuluzi "amanani aphezulu" kubangela izindleko eziphansi zokucubungula kunamathuluzi e-HSS.

Isikhathi sokuthumela: Jun-03-2023