Ithuluzi lingenye yezingxenye ezibalulekile kumathuluzi omshini wokwenza imishini.Ngokuthuthuka kwesayensi nobuchwepheshe, ithuluzi selishintshile lisuka ethuluzini eliyingxubevange lokuqala laya ethuluzini elivalekile elisetshenziswa kakhulu.Ukugaywa kabusha nokunameka kabusha kwe-carbide enosimende namathuluzi ensimbi enesivinini esikhulu kuyizinqubo ezivamile okwamanje.Nakuba intengo yokugaya kabusha ithuluzi noma ukuhlanganisa kabusha iyingxenye encane kuphela yezindleko zokukhiqiza amathuluzi amasha, ingandisa impilo yamathuluzi futhi yehlise izindleko zokukhiqiza.Inqubo yokugaya kabusha iyindlela yokwelapha evamile yamathuluzi akhethekile noma amathuluzi abizayo.Amathuluzi angenziwa kabusha noma ahlanganiswe kabusha ahlanganisa izingcezu zokubhoboza, izinqamuli zokugaya, izinti kanye namathuluzi okwenza.

Ukugaya kabusha ithuluzi

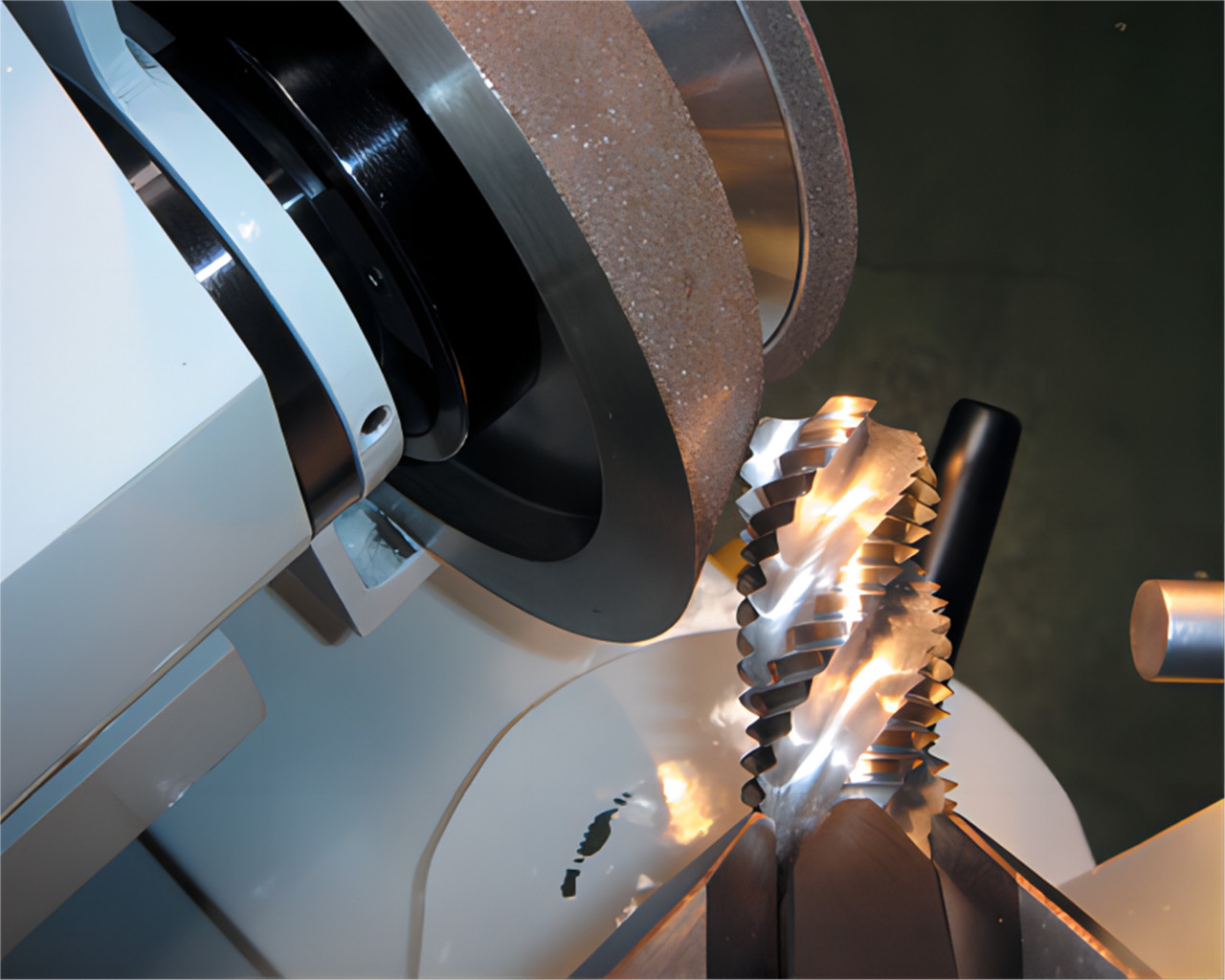

Enqubweni yokugaya kabusha i-drill noma i-milling cutter, kuyadingeka ukugaya unqenqema lokusika ukuze kukhishwe i-coating yasekuqaleni, ngakho-ke isondo lokugaya elisetshenzisiwe kufanele libe nobulukhuni obanele.Ukucutshungulwa kwangaphambili komphetho wokusika ngokuphinda kugaywe kubaluleke kakhulu.Akudingekile kuphela ukuqinisekisa ukuthi ukuma kwejiyomethri konqenqema lokusika kungagcinwa ngokuphelele futhi ngokunembile ngemva kokugaya kabusha ithuluzi, kodwa futhi kudinga ukuthi ithuluzi elihlanganisiwe le-PVD kufanele "liphephe" ukuze liphinde ligaywe.Ngakho-ke, kuyadingeka ukugwema inqubo yokugaya okungenangqondo (njengokugaya okunzima noma ukugaya okomile, lapho indawo yethuluzi yonakaliswa ngenxa yokushisa okuphezulu).

Ukususwa kokunamathela

Ngaphambi kokuba ithuluzi lifakwe kabusha, zonke izimbotshana zokuqala zingasuswa ngezindlela zamakhemikhali.Indlela yokususa amakhemikhali ivamise ukusetshenziselwa amathuluzi ayinkimbinkimbi (njengamahobhu nama-broaches), noma amathuluzi anama-recoating amaningi namathuluzi anezinkinga ezibangelwa ukujiya kokumboza.Indlela yokukhishwa kwamakhemikhali yokugqoka ngokuvamile ikhawulelwe kumathuluzi ensimbi anesivinini esikhulu, ngoba le ndlela izolimaza i-substrate ye-carbide enosimende: indlela yokukhishwa kwamakhemikhali yokugqoka izohlunga i-cobalt kusuka ku-substrate ye-carbide ehlanganisiwe, okuholela ekubunjweni kwe-porosity yendawo. i-substrate, ukwakheka kwama-pores kanye nobunzima bokubuyisela kabusha.

"Indlela yokukhipha amakhemikhali ikhethwa ekususeni ukugqwala kwezingubo eziqinile kunsimbi enesivinini esikhulu."Ngenxa yokuthi i-matrix ye-carbide enosimende iqukethe izingxenye zamakhemikhali ezifana nalezo eziku-coating, i-solvent yokususa amakhemikhali cishe izolimaza i-matrix ye-carbide enosimende kune-matrix yensimbi enesivinini esikhulu.

Ngaphezu kwalokho, kunezindlela ezithile zamakhemikhali ezinelungelo lobunikazi ezifanele ukususa ukunamathela kwe-PVD.Kulezi zindlela zamakhemikhali, kukhona ukusabela kwamakhemikhali okuncane kuphela phakathi kwesisombululo sokususa i-coating kanye ne-matrix ye-carbide enosimende, kodwa lezi zindlela azikasetshenziswa kabanzi okwamanje.Ngaphezu kwalokho, kunezinye izindlela zokuhlanza i-coating, njengokucutshungulwa kwe-laser, ukuqhunyiswa kwe-abrasive, njll. Indlela yokususa amakhemikhali iyindlela evamile kakhulu, ngoba inganikeza ukufana okuhle kokususwa kwe-surface coating.

Njengamanje, inqubo evamile yokubuyisela kabusha iwukuba ukususa ukunamathela kwangempela kwethuluzi ngenqubo yokugaya.

Umnotho wokubuyisela kabusha

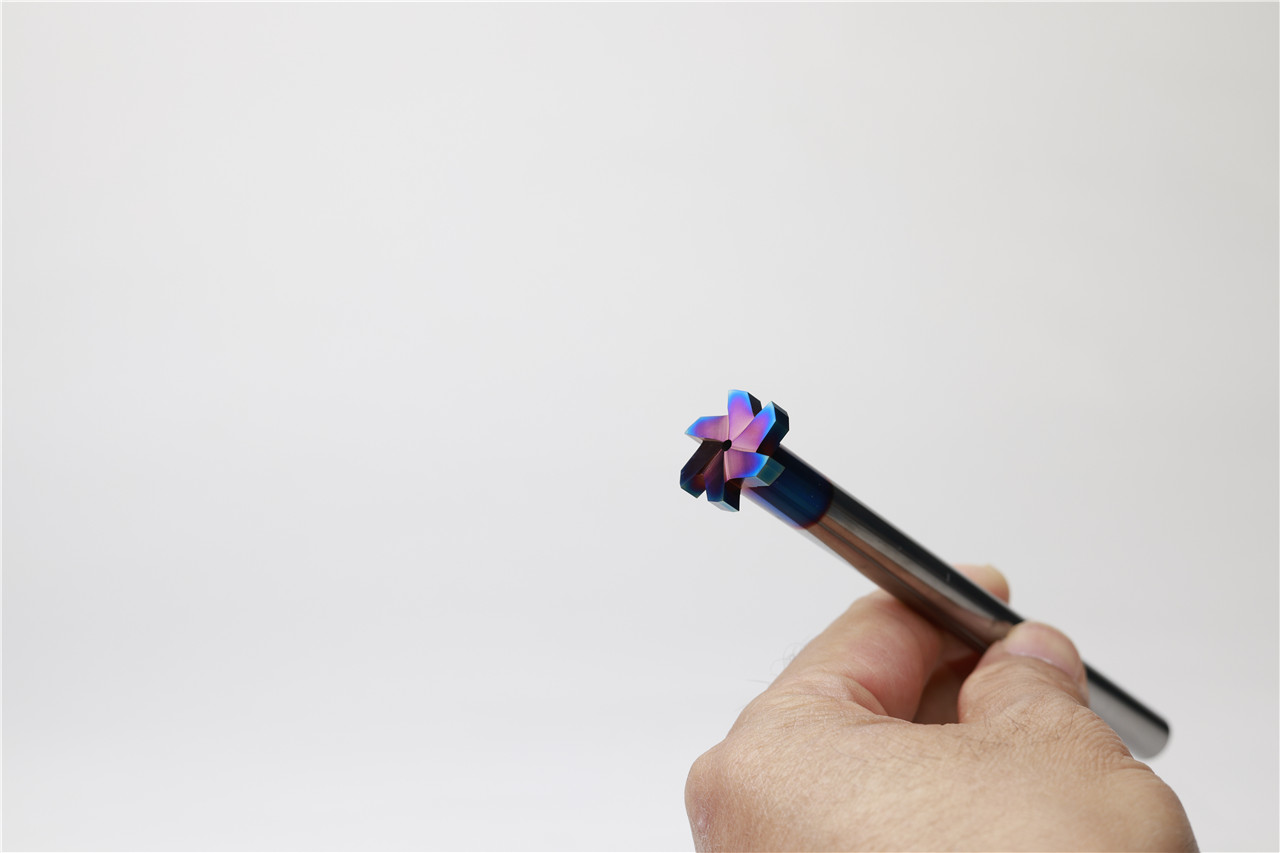

Izingubo zamathuluzi ezivame kakhulu yi-TiN, i-TiC ne-TiAlN.Okunye okufakwe i-superhard nitrogen/carbide coatings nakho kusetshenzisiwe, kodwa akujwayelekile kakhulu.Amathuluzi edayimane e-PVD ahlanganiswe angaphinde afakwe phansi futhi ahlanganiswe kabusha.Ngesikhathi senqubo yokubuyisela kabusha, ithuluzi "lizovikelwa" ukuze ligweme ukulimala endaweni ebalulekile.

Lokhu kuvame ukuba njalo: ngemva kokuthenga amathuluzi angamboziwe, abasebenzisi bangawagqokisa lapho kudingeka ukuba afakwe ngaphansi, noma basebenzise ama-coatings ahlukene kumathuluzi amasha noma amathuluzi angemuva.

Umkhawulo wokubuyisela kabusha

Njengoba nje ithuluzi lingenziwa kabusha izikhathi eziningi, unqenqema lwethuluzi lungabuye luboshwe izikhathi eziningi.Isihluthulelo sokuthuthukisa ukusebenza kwethuluzi ukuthola i-coating ngokunamathela okuhle ebusweni bethuluzi eligcinwe phansi.

Ngaphandle konqenqema lokusika, ingxenye esele yendawo yamathuluzi ingase ingadingeki ukuthi ihlanganiswe noma ifakwe kabusha ngesikhathi sokugaya ngakunye kwethuluzi, kuye ngokuthi hlobo luni lwethuluzi kanye nemingcele yokusika esetshenziswa emishinini.Ama-Hobs nama-broaches angamathuluzi adinga ukususa yonke i-coating yasekuqaleni lapho ehlanganiswa kabusha, ngaphandle kwalokho ukusebenza kwamathuluzi kuzoncishiswa.Ngaphambi kokuba inkinga yokunamathela ebangelwa ukucindezeleka ivelele, ithuluzi lingaphinda lifakwe izikhathi ezimbalwa ngaphandle kokukhipha i-coating endala.Nakuba i-PVD enamathela inezinsalela zokucindezeleka ezicindezelayo ezinenzuzo ekusikeni kwensimbi, le ngcindezi izokhula ngokunyuka kokuqina kwe-coating, futhi ukugqoka kuzoqala ukudilika ngemva kokweqa umkhawulo omisiwe.Uma uvuselela ngaphandle kokukhipha i-coating endala, ubukhulu bengezwe kububanzi obungaphandle bethuluzi.Nge-drill bit, kusho ukuthi ububanzi bembobo bukhula.Ngakho-ke, kuyadingeka ukucabangela umthelela wokushuba okwengeziwe kokumboza kububanzi obungaphandle bethuluzi, kanye nomthelela walokhu okubili ekubekezeleni kobukhulu bobubanzi bomgodi owenziwe ngomshini.

I-drill bit ingahlanganiswa izikhathi ezi-5 kuya kwezingu-10 ngaphandle kokukhipha i-coating endala, kodwa ngemva kwalokho, izobhekana nezinkinga ezinkulu zamaphutha.U-Dennis Klein, iphini likamongameli we-Spec Tools, wayekholelwa ukuthi ukujiya kokumboza ngeke kube inkinga phakathi kwebanga lamaphutha elingu-± 1 µ m;Kodwa-ke, uma iphutha lingaphakathi kwebanga elingu-0.5~0.1 µ m, umthelela wokujiya kokumboza kufanele ucatshangelwe.Inqobo nje uma ukujiya kokumboza kungabi inkinga, amathuluzi anamathiselwe kabusha nangemuva angase abe nokusebenza okungcono kunalawo okuqala.

Isikhathi sokuthumela: Feb-24-2023