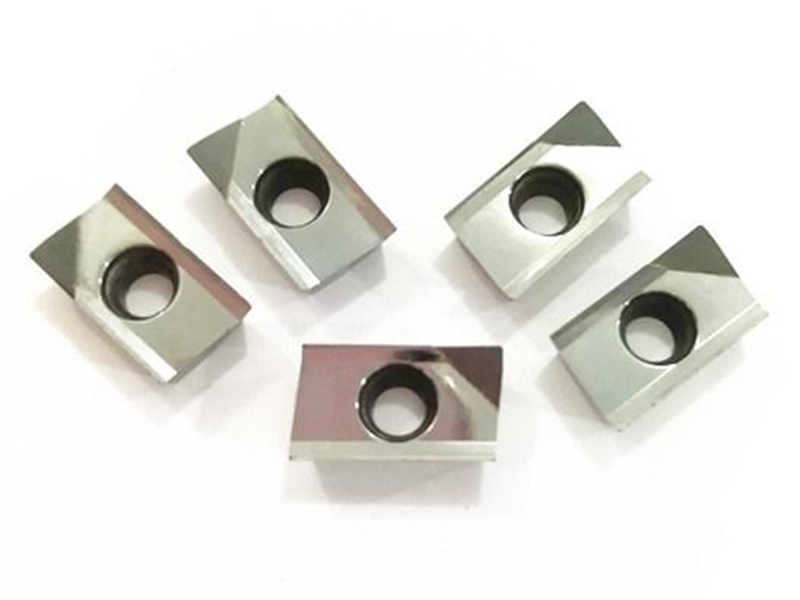

PCD Cutting Ithuluzi CNC Diamond Turning Milling Faka for aluminium

Izinzuzo zomkhiqizo

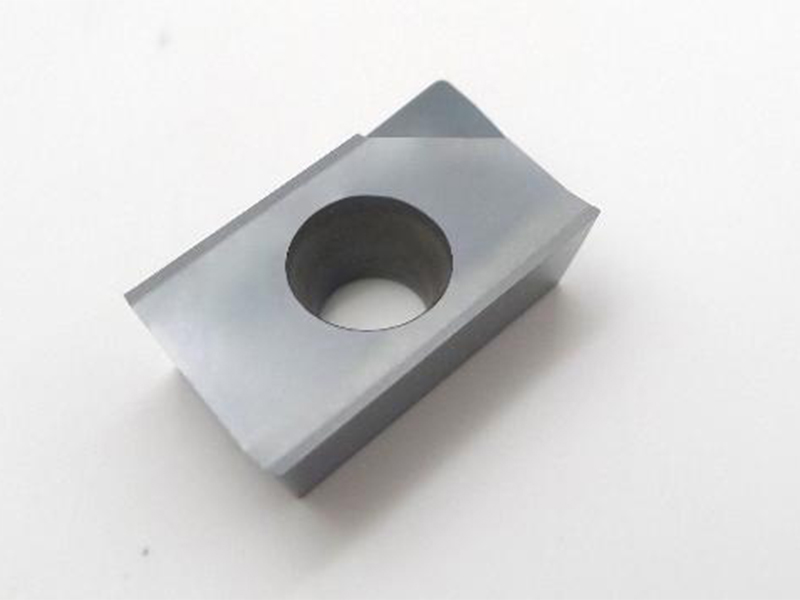

Ukusika okuncane kakhulu, ukwenza imishini enembile

Unqenqema lokusika lwethuluzi ledayimane lingaba phansi licijile kakhulu, i-radius yokusika yendilinga yensimbi ngokuvamile ingafinyelela ku-0.1-0.5 μ m, futhi ithuluzi ledayimane le-crystal elilodwa lemvelo lingafinyelela ku-0.002-0.008 μ m.

Khetha i-PCD eseceleni enhle egcwele bese uthola umphumela ophindwe kabili ngohhafu womzamo

Sebenzisa umphumela we-OPT Full face PCD insert

1. Izindleko eziphansi zokucubungula

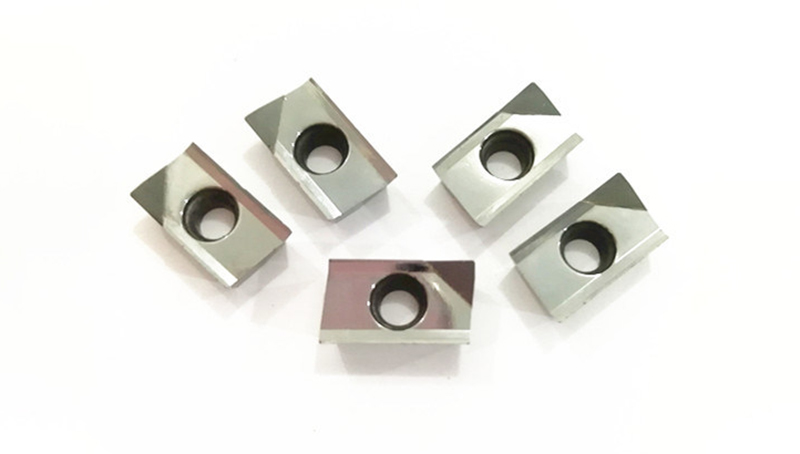

2. Impilo ende yenkonzo

3. Umphumela wokuphenduka nokugaya ugqamile

4. Isikhathi eside esiqhubekayo sokucubungula I-OPT blade icutshungulwa ngokuqhubekayo imizuzu engama-400, futhi i-blade ivamise ukugqokwa ngaphandle kokuphuka.

Ukuqeda okuphezulu, ukwesekwa ngokwezifiso

Ngaphansi kwezimo ezifanayo zokusika, ingasika ngokushesha ngaphandle kokunamathisela i-blade, ngokusebenza kahle okuphezulu kanye nesiphetho esifunayo.

I-blade inokuqina okuphezulu, ubukhali, ukuqina okuhle nokumelana nokugqoka.Izigaba ezahlukahlukene kanye nokucaciswa, okusekela imininingwane eyenziwe ngezifiso.

I-high conductivity eshisayo, impilo ende yesevisi

I-thermal diffusivity ye-diamond cutter iphakeme, futhi ukuqhutshwa kwayo okushisayo yizikhathi ezingu-1.5-9 zaleyo ye-carbide enosimende kanye nezikhathi ezingu-2-6 zethusi.Ukushisa okukhiqizwa ngokusika kulula ukuhlakazeka, futhi izinga lokushisa lengxenye yokusika ithuluzi liphansi.Impilo ende yesevisi.

Izinto ezikhethiwe, ithiphu elikhulu le-PCD eliqinile futhi elingagugi

Khetha i-PCD yekhwalithi ephezulu ne-alloy eqinile enokumelana nokugqokwa izikhathi ezingama-60-80.Lapho kwenziwa izinto ezinobunzima obuphakeme, impilo yamathuluzi edayimane iyizikhathi eziyi-10-100 zamathuluzi e-carbide enosimende, ngisho namakhulu ezikhathi.

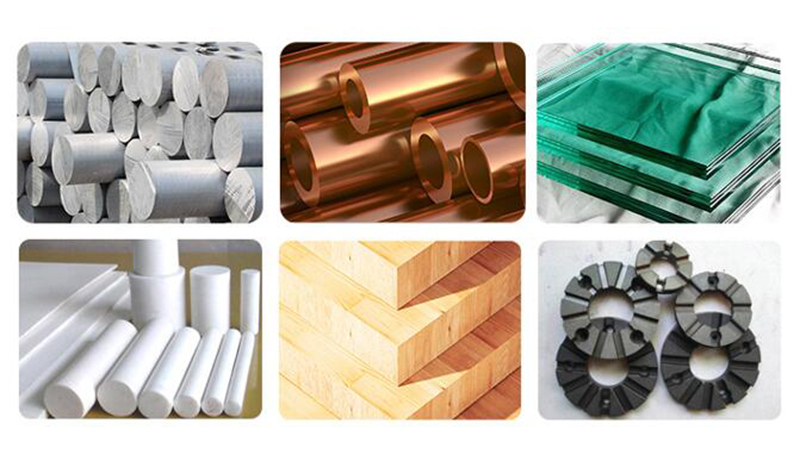

Ukucubungula isivinini esikhulu, umthamo omkhulu wokukhiqiza

Ukufakwa kwedayimane kwe-PCD kulungele ukwenziwa kwemishini enesivinini esikhulu nokomile.Ziyakwazi ukukhetha imishini yesimanje ukuthuthukisa ukusebenza kahle.Abakwazi nje ukwandisa okukhiphayo kwansuku zonke ngaphandle kokutshalwa kwezimali okwengeziwe, kodwa futhi bangasebenzisi uketshezi lokusika.Banobungani bemvelo futhi banokwethenjelwa.

Ukutholwa okuqinile kanye nenqubo eqinile

1. Ukukhethwa okuhle kwezinto ezibonakalayo kanye nokuhlolwa okuqinile kwezinto zokusetshenziswa ukuze kuqinisekiswe izinga eliphezulu lemikhiqizo eqediwe

2. Umtshina ongenisiwe usebenzisa ngokuqinile yonke inqubo yokukhiqiza ukuqinisekisa ukuthi zonke izingxenye zomkhiqizo zingakwanelisa.

| Ubukhulu, mm | |||||

| Uchungechunge | Imodeli No. | d | S | d1 | R |

| SNGN | SNGN090304 | 9.525 | 3.18 | - | 0.4 |

| SNGN090308 | 9.525 | 3.18 | - | 0.8 | |

| SNGN090312 | 9.525 | 3.18 | - | 1.2 | |

| SNGN090316 | 9.525 | 3.18 | - | 1.6 | |

| SNGN120308 | 12.7 | 3.18 | - | 0.8 | |

| SNGN120312 | 12.7 | 3.18 | - | 1.2 | |

| SNGN120408 | 12.7 | 4.76 | - | 0.8 | |

| SNGN120412 | 12.7 | 4.76 | - | 1.2 | |

| Uchungechunge | Imodeli No. | d | Sl | d1 | R |

| SNGA | SNGA090304 | 9.525 | 3.18 | 3.81 | 0.4 |

| SNGA090308 | 9.525 | 3.18 | 3.81 | 0.8 | |

| SNGA120404 | 12.7 | 4.76 | 5.16 | 0.4 | |

| SNGA120408 | 12.7 | 4.76 | 5.16 | 0.8 | |

| SNGA120412 | 12.7 | 4.76 | 5.16 | 1.2 | |

| Ubukhulu, mm | |||||

| Uchungechunge | Imodeli No. | d | S | d1 | R |

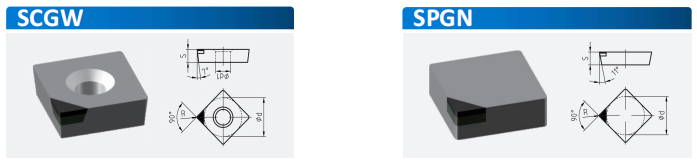

| I-SCGW | I-SCGW060202 | 6.35 | 2.38 | 2.2 | 0.2 |

| I-SCGW060204 | 6.35 | 2.38 | 2.2 | 0.4 | |

| I-SCGW090304 | 9.525 | 3.18 | 4.4 | 0.4 | |

| I-SCGW090308 | 9.525 | 3.18 | 4.4 | 0.8 | |

| I-SCGW09T304 | 9.525 | 3.97 | 4.4 | 0.4 | |

| I-SCGW09T308 | 9.525 | 3.97 | 4.4 | 0.8 | |

| I-SCGW120404 | 12.7 | 4.76 | 5.5 | 0.4 | |

| I-SCGW120408 | 12.7 | 4.76 | 5.5 | 0.8 | |

| Uchungechunge | Imodeli No. | d | S | d1 | R |

| I-SPGN | I-SPGN090304 | 9.525 | 3.18 | - | 0.4 |

| I-SPGN090308 | 9.525 | 3.18 | - | 0.8 | |

| I-SPGN090312 | 9.525 | 3.18 | - | 1.2 | |

| I-SPGN120304 | 12.7 | 3.18 | - | 0.4 | |

| I-SPGN120308 | 12.7 | 3.18 | - | 0.8 | |

| I-SPGN120312 | 12.7 | 3.18 | - | 1.2 | |

| I-SPGN120316 | 12.7 | 3.18 | - | 1.6 | |

| I-SPGN120408 | 12.7 | 4.76 | - | 0.8 | |

| I-SPGN120412 | 12.7 | 4.76 | - | 1.2 | |