Ukuthepha kwe-CNC Thepha ngomtshingo oqondile ompompi we-carbide ompompi wokupholisa wensimbi

- Incazelo yomkhiqizo

Kubasebenzisi abanezimo zokusebenzisa okokupholisa ngesikhathi sokucubungula, impompi ye-carbide epholile yangaphakathi ingahlonyiswa ukuze kuthuthukiswe impilo yamathuluzi.

I-OPT ihlinzeka ngompompi be-carbide abapholile bangaphakathi kanye nompompi abapholile abaseceleni, kuncike esicelweni sabasebenzisi.

izimbobo ezipholile zisebenzisa inhloso ebalulekile ekweluleni impilo yamathuluzi ompompi be-carbide.

Okokuqala, izimbobo zokupholisa zangaphakathi ziqondisa ukupholisa ngqo emaphethelweni okusika, zinciphisa izinga lokushisa lokusika kanye nokungqubuzana.Lokhu akusizi nje kuphela ekuvimbeleni ukushisisa kukampompi kodwa futhi kuthuthukisa ukuphuma kwe-chip.

Okwesibili, ukuba khona kwezimbobo zokupholisa eziseceleni kuhlakaza into epholisayo eduze kwe-tap shank, kuqhubeke kwehlisa izinga lokushisa nempilo kampompi ende.

- Uhlelo lokusebenza olujwayelekile

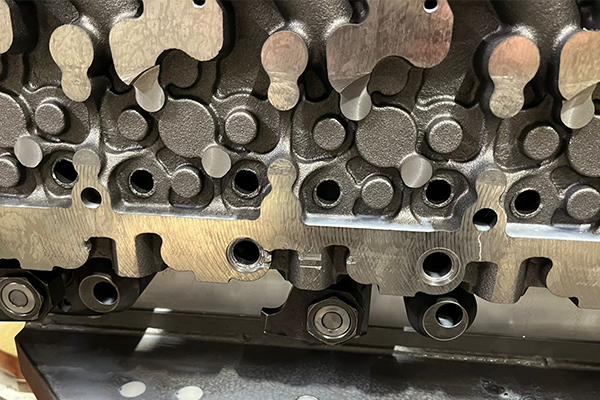

Enye yezinhlelo ezijwayelekile zompompi we-carbide kumshini wamakhanda esilinda enjini yensimbi.Lawa makhanda angamasilinda adlala indima ebalulekile ekusebenzeni kukonke nokuqina kwezinjini.Ngokusetshenziswa kompompi be-carbide, abakhiqizi bafinyelela ukunemba okuphakeme kwentambo, okuholela ekwakhekeni kwezakhiwo zokuvala ezithuthukisiwe kanye namathuba ancishisiwe okuvuza.Ngaphezu kwalokho, impilo yamathuluzi enwetshiwe yompompi be-carbide inika amandla ukukhiqizwa kwenqwaba ngenkathi kugcinwa izindinganiso zekhwalithi ezingashintshi.

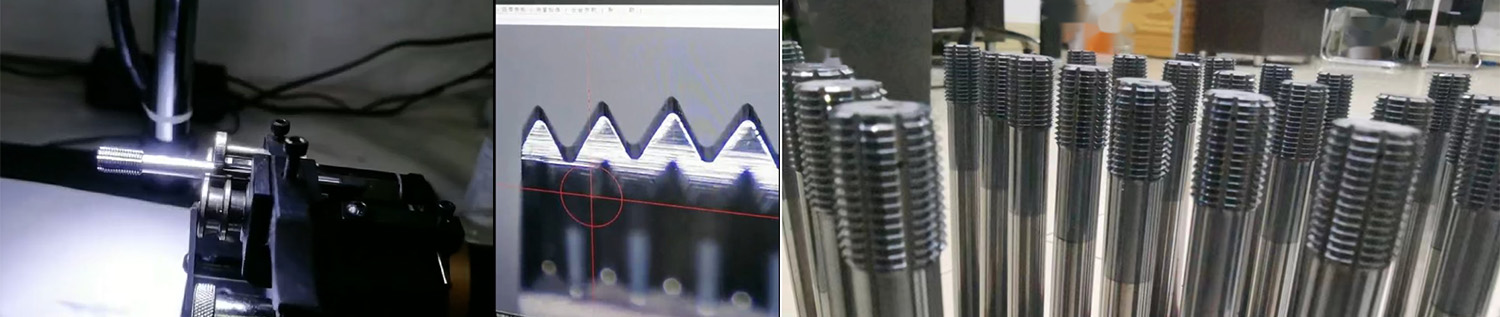

Ukuhlola nokubonisa

Ngaphambi koku-oda, sicela uxhumane nesevisi yethu yamakhasimende angaphambi kokuthengisa:

1. Impahla yokusebenza

2. Ukuthi umkhiqizo ulashwa yini ngemuva kokucubungula

3. Izidingo zokunemba, ubukhulu begeji ye-go kanye ne-go gauge.

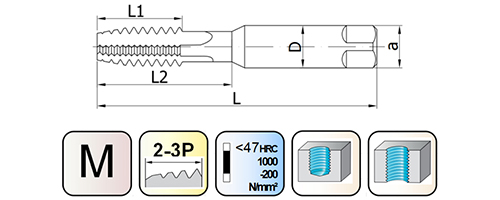

| Ukuqokwa D | Usayizi womucu | Umbala mm | L1 mm | L2 mm | D mm | L mm | Z | a ¨ | I-Pre-drill mm |

| T602-040048-M3x0.5 | M3 | 0.5 | 11 | 18 | 4 | 48 | 4 | 3.15 | 2.46-2.59 |

| T602-040050-M3.5×0.6 | M3.5 | 0.6 | 13 | 21 | 4 | 50 | 4 | 3.15 | 2.85-3.01 |

| T602-050053-M4x0.7 | M4 | 0.7 | 13 | 21 | 5 | 53 | 4 | 4 | 3.25-3.42 |

| T602-060058-M5x0.8 | M5 | 0.8 | 16 | 25 | 6 | 58 | 4 | 4.5 | 4.14-4.33 |

| T602-060066-M6x1 | M6 | 1 | 19 | 30 | 6 | 66 | 4 | 4.5 | 4.92-5.15 |

| T602-080072-M8x1 | M8 | 1 | 22 | 35 | 8 | 72 | 4 | 6.3 | 6.92-7.15 |

| T602-080072-M8x1.25 | M8 | 1.25 | 22 | 35 | 8 | 72 | 4 | 6.3 | 6.65-6.91 |

| T602-080080-M10x1 | M10 | 1 | 24 | - | 8 | 80 | 4 | 6.3 | 8.92-9.16 |

| T602-100080-M10x1 | M10 | 1 | 24 | 38 | 10 | 80 | 4 | 8 | 8.92-9.16 |

| T602-080080-M10x1.25 | M10 | 1.25 | 24 | - | 8 | 80 | 4 | 6.3 | 8.65-8.91 |

| T602-100080-M10x1.25 | M10 | 1.25 | 24 | 38 | 10 | 80 | 4 | 8 | 8.65-8.91 |

| T602-080080-M10x1.5 | M10 | 1.5 | 24 | - | 8 | 80 | 4 | 6.3 | 8.38-8.67 |

| T602-100080-M10x1.5 | M10 | 1.5 | 24 | 38 | 10 | 80 | 4 | 8 | 8.38-8.67 |

| T602-100089-M12x1.25 | M12 | 1.25 | 29 | - | 10 | 89 | 4 | 8 | 10.65-10.91 |

| T602-120089-M12x1.25 | M12 | 1.25 | 29 | 46 | 12 | 89 | 4 | 10 | 10.65-10.91 |

| T602-100089-M12x1.5 | M12 | 1.5 | 29 | - | 10 | 89 | 4 | 8 | 10.38-10.67 |

| T602-120089-M12x1.5 | M12 | 1.5 | 29 | 46 | 12 | 89 | 4 | 10 | 10.38-10.67 |

| T602-100089-M12x1.75 | M12 | 1.75 | 29 | - | 10 | 89 | 4 | 8 | 10.11-10.44 |

| T602-120089-M12x1.75 | M12 | 1.75 | 29 | 46 | 12 | 89 | 4 | 10 | 10.11-10.44 |

| T602-120095-M14x1.5 | M14 | 1.5 | 30 | - | 12 | 95 | 4 | 10 | 12.38-12.67 |

| T602-120095-M14x2 | M14 | 2 | 30 | - | 12 | 95 | 4 | 10 | 11.84-12.2 |

| T602-120102-M16x2 | M16 | 2 | 32 | - | 12 | 102 | 4 | 10 | 13.9-14.2 |