I-Carbide tap yensimbi eqinile Umtshingo oqondile Tap Metric, umpompi we-UNC

- Incazelo yomkhiqizo

Ompompi abenziwe ngezinto ze-HSSE noma ze-HSSE-PM bafaneleke kuphela ukucubungula izinto ezinobunzima obungaphansi kwe-HRC49.Ngakho-ke, kuma-workpieces angaphandle kwalolu hlu lobulukhuni, ukuthepha kwe-carbide kuba yisinqumo esikhethwayo sokucubungula.

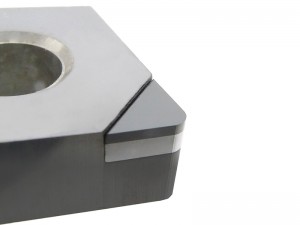

I-OPT carbide tap yensimbi eqinile ene-germery yayo ekhethekile yamaphrofayili omtshingo kanye nama-engeli ayo akhethekile we-rake nama-engeli okusiza enza insimbi yokusika insimbi ihlale isikhathi eside, isetshenziswa kubulukhuni bengcezu yokusebenza ye-HRC55-63

I-TiCN noma i-ALTiN isetshenziselwa ukuthuthukisa ubulukhuni futhi ukumelana nokugqokwa kuthuthukisa impilo yamathuluzi.

Ngokwesicelo somsebenzisi wokugcina, umholi wefomu le-Chamfer ngokuvamile angaba imicu engu-2-3 noma imicu engu-4-5, ngokuvamile kufanele isetshenziswe kumishini ye-CNC, isethi kampompi nayo iyatholakala ukuze isetshenziswe u-manuel.

- Uhlelo lokusebenza olujwayelekile

Eminyakeni yakamuva, isidingo somshini wokunemba wezingxenye ezenziwe ngensimbi eqinile sikhule kakhulu.Ukwanda kokusetshenziswa kwensimbi eqinile ezimbonini ezifana nezezimoto, i-aerospace, kanye neyokukhiqiza kwenza kudingeke ukuthi kusetshenziswe amathuluzi akhethekile akwazi ukuphatha ngempumelelo amazinga aphezulu okuqina.Ompompi be-Carbide abaklanyelwe ukufakwa kwensimbi eqinile sebebaluleke kakhulu kulokhu.

Kubalulekile ukukhetha impompi ye-carbide efanele yohlelo ngalunye oluthile.

I-OPT izibophezele ekwenzeni ama-thread machining ezimbonini ezehlukene, ngokusho kwezixazululo zemishini ehambisana nekhasimende, ukuletha amakhasimende imiphumela engcono yokucubungula nokusebenza kahle kokukhiqiza.

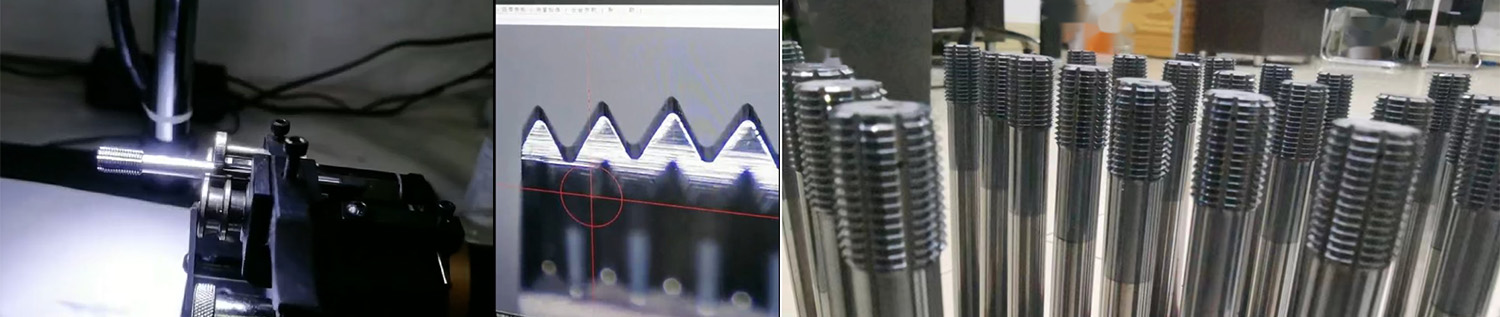

Ukuhlola nokubonisa

Ngaphambi koku-oda, sicela uxhumane nesevisi yethu yamakhasimende angaphambi kokuthengisa:

1. Impahla yokusebenza

2. Ukuthi umkhiqizo ulashwa yini ngemuva kokucubungula

3. Izidingo zokunemba, ubukhulu begeji ye-go kanye ne-go gauge.