Uma sithinta uchungechunge, kunezinhlobo eziningi zokuthepha ongakhetha kuzo.Singazikhetha kanjani?Njengokucofa insimbi eqinile, ukucofa insimbi, noma ukucofa i-aluminium, kufanele senze kanjani?

Yebo, zonke zisetshenziselwa ukuthepha izintambo, kodwa ukukhetha umpompi ofanelekayo kudinga ukuqonda ucezu lwakho lokusebenza nezimo zokusebenza, njengempahla ye-workpiece ecutshungulwayo, ubukhulu nokujula kwembobo engezansi yentambo, nokuthi ingabe kukhona ukuphazamiseka, ukuze wenze ukucubungula kwakho kusebenze kahle futhi kusebenze kahle.

Ukuhlukaniswa kuhlukaniswe ikakhulukazi izigaba ezimbili ezilandelayo ngokusekelwe ekubukekeni nesakhiwo:

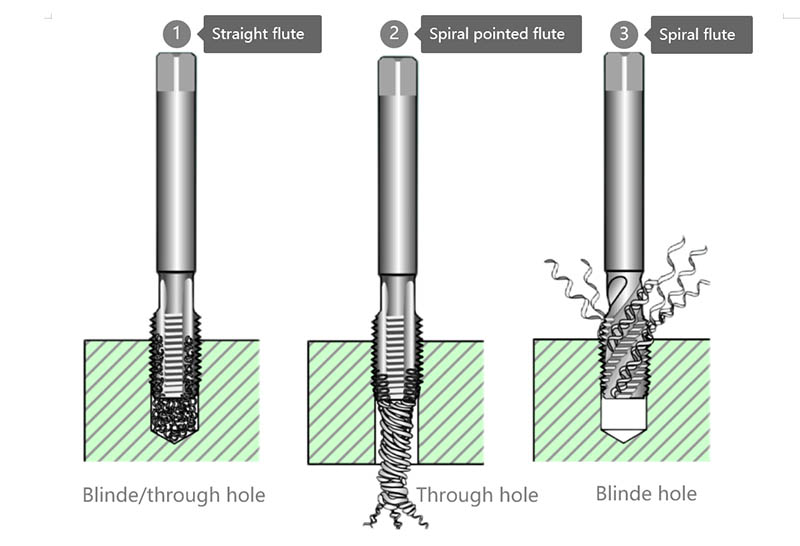

1.Umpompi womtshingo oqondile: isetshenziselwa ukucubungula ngokusebenzisa nezimbobo eziyimpumputhe.Ama-iron chips akhona ku-tap groove, futhi ikhwalithi yochungechunge olucutshunguliwe ayiphezulu.Isetshenziswa kakhulu ekucubunguleni izinto ezimfishane ze-chip, njenge-grey cast iron.

2.Umpompi ocijile: imvamisa isetshenziswa kuphela ezimbotsheni, ngesilinganiso sobude ukuya kobubanzi obufika ku-3D~3.5D, ama-iron chips akhishelwa phansi, i-torque yokusika ephansi, kanye nekhwalithi ephezulu yomucu ocutshunguliwe.Kwaziwa nangokuthi tap ye-edge edge noma i-tip tap.

Lapho usika, kuyadingeka ukuqinisekisa ukuthi zonke izingxenye zokusika zingena, ngaphandle kwalokho ukuphuka kwamazinyo kungase kwenzeke.

3.Umpompi womtshingo ovunguzayo: isetshenziselwa ukucubungula imbobo eyimpumputhe enembobo ejulile engaphansi noma elingana ne-3D.Ama-ayoni chips akhishwa eduze kwe-spiral groove, okuholela kukhwalithi ephezulu yocingo.

I-10-20 ° spiral angle tap ingacubungula ukujula kwentambo kuze kufike ku-2D;I-28-40 ° spiral angle tap ingacubungula ukujula kwentambo kuze kufike ku-3D;I-50 ° spiral angle tap ingacubungula ukujula kochungechunge kufika ku-3.5D (isimo esikhethekile sokusebenza esingu-4D).

Ngezinye izikhathi (izinto eziqinile, izigxobo zamazinyo ezinkulu, njll.), ukuze kuzuzwe amandla angcono wethiphu yezinyo, ompompi bomtshingo ovunguzayo basetshenziselwa ukucubungula ngokusebenzisa izimbobo.

Ukwakha ompompi u-aslo wabizaThepha okungenamtshingo,Ukugoqa umpompi

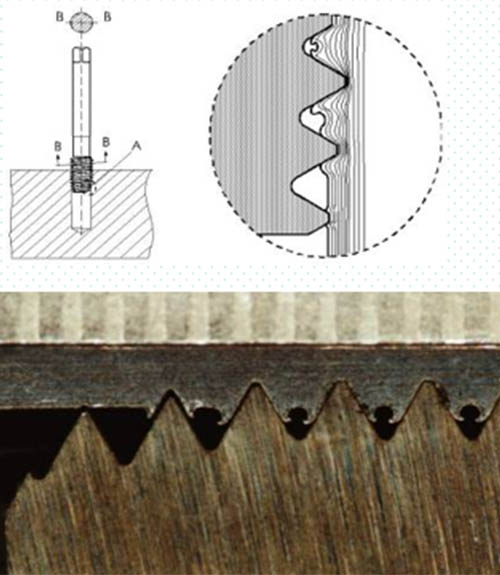

Ingasetshenziselwa ukucubungula ngokusebenzisa izimbobo nezimbobo eziyizimpumputhe, ukwakha izimo zamazinyo ngokusebenzisa i-plastic deformation yezinto zokwakha, futhi ingasetshenziswa kuphela ukucubungula izinto zepulasitiki.

Ubushelelezi obuphezulu bentambo ekhishwe ngompompi wefomu buphelele, izintambo zensimbi zentambo aziphuli, futhi ungqimba oluqinile olubandayo lwakhiwe phezulu, olungathuthukisa amandla nokugqoka ukumelana kwentambo.

Phakathi kwabo bonke ompompi, ukwenza imicu yikona okuphelele kakhulu, okunamandla amakhulu okuqina kanye nezinga lokufaneleka lentambo, inqobo nje uma imbobo ephansi ifanelekile.

Izici eziyinhloko:

1. Sebenzisa i-deformation yepulasitiki ye-workpiece ukucubungula imicu;

2. Impompi inendawo enkulu ephambanayo, amandla aphezulu, futhi ayiphuka kalula;

3. Ijubane lokusika lingaba phezulu kunompompi wokusika, futhi ukukhiqiza nakho kuyanda ngokufanele;

4. Ngenxa yokucubungula okubandayo kwe-extrusion, izakhiwo zemishini ye-thread surface ecutshungulwayo ziyathuthukiswa, ukugoqa kwendawo kuphezulu, futhi amandla entambo, ukumelana nokugqoka, nokumelana nokugqwala kuyathuthukiswa;

5. Ukucubungula mahhala kwe-chip.

Amaphutha ayo yilezi:

Ingasetshenziswa kuphela ukucubungula izinto zepulasitiki;

Kunamafomu amabili esakhiwo:

1. Umpompi owakhelwe umsele ongewona uwoyela usetshenziswa kuphela esimweni sokusebenza sokuhlanganisa imbobo eyimpumputhe eqondile;

2 ompompi abakha imisele kawoyela bafanele zonke izimo zokusebenza, kodwa ngokuvamile ompompi abancane abanobubanzi abaklanywanga ngemisele kawoyela ngenxa yobunzima bokukhiqiza.

Isikhathi sokuthumela: Oct-11-2023