Njengoba kwaziwa kahle, ukubuyisela kabusha kuyinqubo yokugcina ohlelweni lwembobo.Uma izici ezithile ziwuthinta, kungenzeka ukuthi imikhiqizo eqediwe efanelekayo izophenduka imikhiqizo yokulahlwa ngaso leso sikhathi.Ngakho yini okufanele siyenze uma sihlangabezana nezinkinga?Amathuluzi okusika e-OPT ahlele izinkinga ezithile kanye nezinyathelo ezivela ekusetshenzisweni okungokoqobo kwe-Reamer, ngethemba lokuthi ungathola imininingwane ethile esihlokweni.

1. Ubulukhuni obungebuhle bembobo yangaphakathi

isizathu

1.Ijubane lokusika liphezulu kakhulu.

2.Ukukhethwa koketshezi lokusika akulungile.

3.I-engeli eyinhloko yokuchezuka ye-remer inkulu kakhulu, futhi unqenqema lokusika lwe-reamer alukho kusiyingi esifanayo.

4.Isibonelelo sokubuyisela kabusha sikhulu kakhulu, asilingani noma sincane kakhulu, futhi indawo yasendaweni ayiqanjwa kabusha.

5.Ukuphambuka kwe-swing yengxenye yokusika ye-reamer kudlula ukubekezelelana, umkhawulo wokusika awubukhali, futhi ubuso bubuhlungu.

6.I-cut cut ye-remer ibanzi kakhulu.

7.Ukukhishwa okungalungile kwe-chip ngesikhathi sokuvuselelwa kabusha.

8.Ukuguga ngokweqile kwe-remer.

9.I-remer ilimele, ishiya ama-burrs noma i-chipping onqenqemeni.

10.Kukhona ukunqwabelana kwemfucumfucu onqenqemeni lokusika.

11.Ngenxa yezingqinamba zezinto ezibonakalayo, ayilungele idigri enguziro noma ama-reamers e-rake engele negative.

Izinyathelo zokuphendula

1. Yehlisa isivinini sokusika.

2. Khetha Ukusika uketshezi ngokwezinto zokucubungula.

3. Yehlisa i-engeli eyinhloko yokuchezuka ngokufanele futhi ugaye unqenqema lokusika ngendlela efanele.

4. Yehlisa isibonelelo sokubuyisela kabusha ngendlela efanele.

5. Thuthukisa ukunemba kanye nekhwalithi yendawo yembobo engezansi ngaphambi kokuvuselela kabusha noma ukwandisa isibonelelo sokubuyisela kabusha.

6. Gaya ububanzi bebhande le-blade.

7. Nciphisa inani lamazinyo kumshini ovuselelayo ngokuya ngesimo esithile, wandise isikhala se-chip ephethe umsele, noma sebenzisa i-remer ene-engeli yokuthambekela kwe-blade ukuze uqinisekise ukususwa kwe-chip okushelelayo.

8. Faka esikhundleni se-reamer njalo futhi ususe indawo yokugaya ngesikhathi sokugaya i-blade.

9. Ngesikhathi sokugaya, ukusetshenziswa, kanye nokuthuthwa kwe-remer, izinyathelo zokuzivikela kufanele zithathwe ukuze kugwenywe ukungqubuzana.

10. Ngomshini ophindayo olimele, sebenzisa itshe lamafutha elicolisekile ukuze ulilungise noma ulishintshe.

2. Ukuyindilinga kwembobo yangaphakathi

isizathu

1. I-remer yinde kakhulu futhi ayinakho ukuqina, okuholela ekudlidlizeni ngesikhathi sokubuyisela kabusha.

2. I-engeli enkulu yokuchezuka ye-remer incane kakhulu.

3. Umkhawulo wokusika we-remer mncane.

4. Imvume yokubuyisela kabusha eyeqile.

5. Kunamanotshi kanye nezimbobo eziphambanayo ebusweni bomgodi ongaphakathi.

6. Kunemigodi yesihlabathi kanye nezimbotshana ebusweni bomgodi.

7. Ibhodi lokuphotha likhululekile, awukho umkhono oqondisayo, noma imvume phakathi kwe-reamer nomkhono womhlahlandlela inkulu kakhulu, noma ucezu lokusebenza lukhubazekile ngemva kokususwa ngenxa yokubamba okuqinile kwezingcezu zokusebenza ezinezindonga ezincane.

Izinyathelo zokuphendula

1. Ama-Reamers anokuqina okunganele angasebenzisa ama-reamers anephimbo lamazinyo elingalingani, futhi ukufakwa kwesixhumi esiphindayo kufanele kusebenzise izixhumo eziqinile ukuze kwandiswe i-engeli enkulu yokuchezuka.

2. Khetha ama-reamer afanelekayo futhi ulawule ukubekezelelana kwendawo yembobo yenqubo yokucubungula kwangaphambili.Ukusebenzisa ama-pitch reamers angalingani nokusebenzisa imikhono eqondisayo emide futhi enembe kakhudlwana;Khetha izikhala ezifanelekayo.

3.Lapho kusetshenziswa ama-pitch reamers alinganayo ukuze kukhishwe izimbobo ezinembe kakhudlwana, ukucaciswa kokuphotha kwethuluzi lomshini kufanele kulungiswe, futhi imvume efanelekile yomkhono womhlahlandlela kufanele kube izindlela zokubopha eziphakeme noma ezifanele kufanele zisetshenziswe ukuze kuncishiswe amandla okubamba.

3. Umugqa omaphakathi awuqondile

isizathu

1. Ukuchezuka kokumba ngaphambi kokuphinda kufakwe kabusha, ikakhulukazi lapho imbobo incane, ayikwazi ukulungisa ukugoba kwasekuqaleni ngenxa yokungaqini kahle kwesixhumi.

2. I-engeli enkulu yokuchezuka ye-remer inkulu kakhulu;Isiqondiso esingesihle senza kube lula kumuntu ophindayo ukuthi achezuke endleleni ngesikhathi sokubuyisela kabusha.

3. Ikhoni ehlanekezelwe yengxenye yokusika inkulu kakhulu.

4. I-reamer ishintsha esikhaleni sembobo ephakathi.

5.Uma isandla sibuyisela kabusha, amandla eqile asetshenziswa ohlangothini olulodwa, okuphoqa ukuthi ophindayo atshekele ngasekugcineni, okulimaza amadigri amile angu-5 wokuphinda afakwe kabusha.

Izinyathelo zokuphendula

1. Khulisa inqubo yokwandisa noma imigodi eyisicefe ukulungisa izimbobo.

2. Yehlisa i-engeli enkulu yokuchezuka.

3. Lungisa i-reamer efanele.

4. Faka enye ingxenye eqondisayo noma ingxenye enwetshiwe yokusika.

4. Ukwanda kokuvuleka

isizathu

1. Inani ledizayini le-diameter yangaphandle ye-reamer likhulu kakhulu noma kukhona ama-burrs onqenqemeni lokusika lwe-reamer.

2. Ijubane lokusika liphezulu kakhulu.

3. Izinga lokuphakelayo elingalungile noma isibonelelo sokwenza imishini.

4. I-engeli enkulu yokuchezuka ye-remer inkulu kakhulu;I-remer igobile.

5. Kukhona isigaxa se-chip esinamathiselwe onqenqemeni lokusika le-hinge.

6. Uma ugaya, ukuphambuka kwe-swing ye-hinge cutting edge kudlula ukubekezelelana.

7. Ukukhethwa koketshezi lokusika akulungile.

8. Uma ufaka i-reamer, ingaphezulu lesibambo sekhoni alihlanzwa ngamabala kawoyela noma kukhona amaqhubu kanye nemihuzuko endaweni yekhoni.

9. Umsila oyisicaba wesibambo se-taper uyasuswa futhi uphazamisa i-taper yesibambo se-taper ngemva kokufakwa ku-spindle yethuluzi lomshini.

10. I-spindle igobile noma amabhodi okuphotha axege kakhulu noma alimele.

11. Ukuntanta kwe-remer akuguquki.

12. Uma i-eksisi ihlukile kucezu lokusebenza kanye nokuphindaphinda kwesandla, amandla akuzo zombili izandla awalingani, okubangela ukuthi ophindayo anyakaze kwesokunxele nakwesokudla.

Izinyathelo zokuphendula

1. Inani ledizayini le-diameter yangaphandle ye-reamer likhulu kakhulu noma kukhona ama-burrs onqenqemeni lokusika lwe-reamer.

2. Ijubane lokusika liphezulu kakhulu.

3. Izinga lokuphakelayo elingalungile noma isibonelelo sokwenza imishini.

4. I-engeli enkulu yokuchezuka ye-remer inkulu kakhulu;I-remer igobile.

5. Kukhona isigaxa se-chip esinamathiselwe onqenqemeni lokusika le-hinge.

6. Uma ugaya, ukuphambuka kwe-swing ye-hinge cutting edge kudlula ukubekezelelana.

7. Ukukhethwa koketshezi lokusika akulungile.

8. Uma ufaka i-reamer, ingaphezulu lesibambo sekhoni alihlanzwa ngamabala kawoyela noma kukhona amaqhubu kanye nemihuzuko endaweni yekhoni.

9. Umsila oyisicaba wesibambo se-taper uyasuswa futhi uphazamisa i-taper yesibambo se-taper ngemva kokufakwa ku-spindle yethuluzi lomshini.

10. I-spindle igobile noma amabhodi okuphotha axege kakhulu noma alimele.

11. Ukuntanta kwe-remer akuguquki.

12. Uma i-eksisi ihlukile kucezu lokusebenza kanye nokuphindaphinda kwesandla, amandla akuzo zombili izandla awalingani, okubangela ukuthi ophindayo anyakaze kwesokunxele nakwesokudla.

5. Kukhona imiphetho ebusweni bomgodi ongaphakathi

Isizathu

1. Imvume yokubuyisela kabusha eyeqile.

2. I-engeli yokusika ye-remer inkulu kakhulu.

3. I-cut cut ye-remer incane kakhulu.

4. Kukhona izimbotshana, izimbobo zesihlabathi, nokuphuma ngokweqile kwe-spindle ebusweni bomsebenzi wokusebenza.

Izinyathelo zokuphendula

1. Nciphisa imvume yokuthola kabusha.

2. Yehlisa i-angle yangemuva yesigaba sokusika.

3. Gaya ububanzi bebhande le-blade.

4. Khetha izikhala ezifanelekayo.

6. Isibambo esiphukile

Isizathu

1. I-remer yinde kakhulu futhi ayinakho ukuqina, okuholela ekudlidlizeni ngesikhathi sokubuyisela kabusha.

2. I-engeli enkulu yokuchezuka ye-remer incane kakhulu.

3. I-hinge encane yokusika enqenqemeni yebhande;Imvume yokubuyisela kabusha eyeqile.

4. Kunamanotshi kanye nezimbobo eziphambanayo ebusweni bomgodi ongaphakathi.

5. Kunemigodi yesihlabathi kanye nezimbotshana ebusweni bomgodi.

6. Ibhodi lokuphotha likhululekile, alinawo umkhono oqondisayo, noma imvume phakathi kwe-reamer nomkhono womhlahlandlela inkulu kakhulu, noma ngenxa yokufakwa kwezinto zokusebenza ezinezindonga ezincane.

7. I-clamp iqine kakhulu futhi i-workpiece iyawohloka ngemva kokususwa.

Izinyathelo zokuphendula

1. Yehlisa isivinini sokusika.

2. Khetha Ukusika uketshezi ngokwezinto zokucubungula.

3. Yehlisa i-engeli eyinhloko yokuchezuka ngokufanele futhi ugaye unqenqema lokusika ngendlela efanele.

4. Yehlisa isibonelelo sokubuyisela kabusha ngendlela efanele.

5. Thuthukisa ukunemba kanye nekhwalithi yendawo yembobo engezansi ngaphambi kokuvuselela kabusha noma ukwandisa isibonelelo sokubuyisela kabusha.

6. Gaya ububanzi bebhande le-blade.

7. Nciphisa inani lamazinyo kumshini ovuselelayo ngokuya ngesimo esithile, wandise isikhala se-chip ephethe umsele, noma sebenzisa i-remer ene-engeli yokuthambekela kwe-blade ukuze uqinisekise ukususwa kwe-chip okushelelayo.

8. Faka esikhundleni se-reamer njalo futhi ususe indawo yokugaya ngesikhathi sokugaya i-blade.

9. Ngesikhathi sokugaya, ukusetshenziswa, kanye nokuthuthwa kwe-remer, izinyathelo zokuzivikela kufanele zithathwe ukuze kugwenywe ukungqubuzana.

10. Ngomshini ophindayo olimele, sebenzisa itshe lamafutha elicolisekile ukuze ulilungise noma ulishintshe.

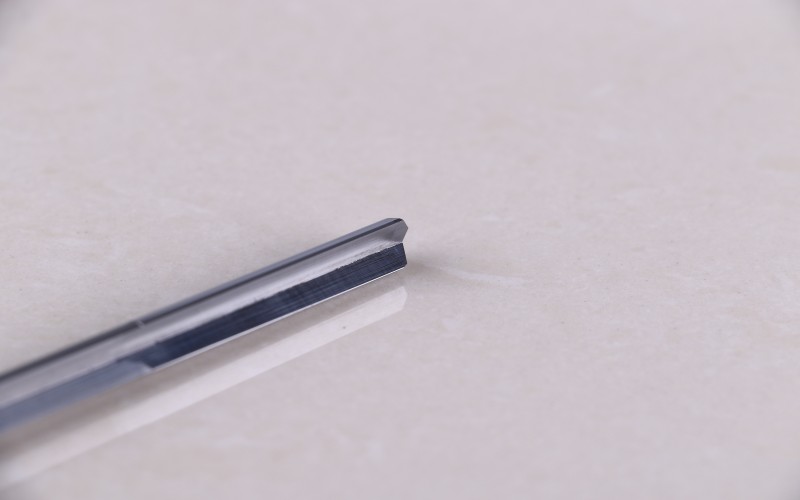

Yebo, kufanele ube nomhlinzeki wamathuluzi omuhle kakhulu.Amathuluzi okusika we-OPT ungumnikezeli wekhwalithi ephezulu onguchwepheshe ekukhiqizeni okuhlukahlukene okujwayelekile/okungajwayelekile i-carbide reamerfuthiPCD reamer

I-Shenzhen OPT Cutting Tool Co., Ltd. enye yomkhiqizi ohamba phambili e-China, amakhono ekuthuthukiseni nasekukhiqizeni ama-carbides namathuluzi edayimane e-PCD

Isikhathi sokuthumela: Jun-16-2023